A Production Operator in the oil and petrochemical industry is responsible for operating and monitoring equipment used in the extraction and processing of oil and gas. They ensure safe and efficient production by conducting routine inspections, troubleshooting issues, and maintaining compliance with industry safety standards. Proficiency in handling complex machinery and understanding process control systems is essential for optimizing output and minimizing downtime.

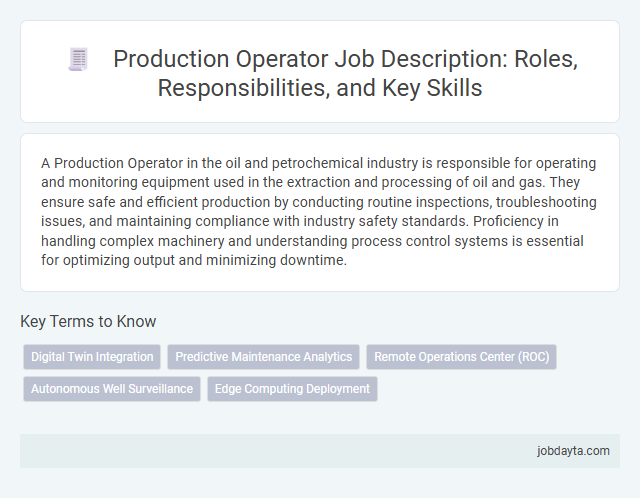

Overview of a Production Operator in the Oil Industry

| Role | Production Operator |

|---|---|

| Industry | Oil and Gas |

| Primary Responsibilities | Monitor and control oil production equipment, ensure safe operations, perform regular maintenance, collect production data, troubleshoot operational issues |

| Key Skills | Mechanical aptitude, equipment monitoring, safety compliance, problem-solving, basic electrical knowledge |

| Typical Work Environment | Oil fields, production facilities, control rooms, remote locations with exposure to outdoor conditions |

| Certification and Training | OSHA safety training, hazardous materials handling, process operations certification, on-the-job training |

| Shift Structure | 24/7 coverage with rotating shifts including nights, weekends, and holidays |

| Impact on Oil Production | Ensures continuous, efficient extraction and processing of hydrocarbons, minimizes downtime, maintains equipment integrity |

| Tools and Equipment | Pumps, valves, control systems, meters and gauges, safety gear |

| Safety Focus | Adherence to industry safety standards, emergency response readiness, environmental compliance |

Key Roles and Responsibilities of Production Operators

Production Operators play a critical role in the efficient extraction and processing of oil and gas resources. Your responsibility is to ensure smooth operations and maintain safety standards throughout the production process.

- Monitor Equipment - Continuously observe machinery and instrumentation to detect malfunctions or irregularities.

- Operate Control Systems - Manage automated and manual control systems to maintain optimal production levels.

- Perform Maintenance - Conduct routine inspections and basic repairs to prevent downtime and enhance equipment longevity.

Essential Skills Required for Production Operators

Production Operators in the oil industry must possess strong technical skills to manage and monitor drilling equipment effectively. Knowledge of safety protocols and environmental regulations is crucial to maintain operational integrity.

Attention to detail and problem-solving abilities ensure smooth production processes and quick response to equipment malfunctions. Your ability to work under pressure and communicate clearly with team members is essential for maintaining a safe work environment.

Daily Tasks and Workflow of Oil Production Operators

Oil Production Operators monitor and control the equipment used in extracting crude oil from wells. They ensure the smooth operation of pumps, separators, and other production machinery to maintain optimal oil flow.

Your daily tasks include inspecting equipment, recording data, and adjusting controls to meet production targets. Operators also troubleshoot mechanical issues and coordinate with maintenance teams to prevent downtime.

Safety Protocols and Compliance in Production Operations

Production Operators in the oil industry play a critical role in ensuring the safe and efficient extraction of petroleum resources. Adherence to strict safety protocols significantly reduces the risk of accidents and environmental hazards during production operations.

Compliance with industry regulations such as OSHA standards and API guidelines is mandatory for Production Operators to maintain workplace safety and operational integrity. Regular safety training and equipment inspections are essential to identify potential hazards early. Effective communication and teamwork further enhance the adherence to safety protocols on-site, minimizing downtime and protecting personnel.

Technical Knowledge and Equipment Handling Skills

What technical knowledge is essential for a Production Operator in the oil industry? Understanding reservoir characteristics, drilling techniques, and safety protocols ensures efficient and safe production processes. Expertise in interpreting well logs and monitoring equipment performance is crucial for optimizing output.

How important are equipment handling skills for a Production Operator? Proficiency in operating pumps, valves, and control systems prevents downtime and maintains production flow. Skilled handling of maintenance tools enhances equipment longevity and reduces operational risks.

Can your ability to troubleshoot equipment impact oil production efficiency? Rapid identification and resolution of mechanical faults minimize production delays. Technical problem-solving skills contribute to maintaining consistent output and safety standards.

Importance of Teamwork and Communication in Production

Effective teamwork and clear communication are essential in oil production operations to ensure safety and efficiency. Your role as a Production Operator depends heavily on collaborating with colleagues and sharing accurate information.

- Teamwork enhances safety - Coordinated efforts reduce the risk of accidents and improve emergency response times.

- Clear communication boosts productivity - Sharing precise data and instructions minimizes errors and downtime.

- Collaborative problem-solving drives innovation - Joint discussions lead to smarter solutions and optimized production processes.

Challenges Faced by Production Operators in Oil Fields

Production operators in oil fields encounter numerous challenges that impact operational efficiency and safety. These challenges require specialized skills and constant adaptation to evolving technologies and environmental conditions.

- Harsh Working Conditions - Operators endure extreme temperatures, remote locations, and hazardous environments that increase physical and mental strain.

- Equipment Maintenance - Continuous monitoring and timely repairs of complex machinery are critical to prevent costly downtime and ensure safety.

- Environmental Compliance - Production operators must adhere to strict regulations to minimize environmental impact and avoid legal penalties.

Overcoming these challenges is essential for maintaining productivity and safety standards in oil field operations.

Training and Certification Requirements for Production Operators

Production operators in the oil industry must complete rigorous training programs that cover safety protocols, equipment operation, and emergency response. Certification requirements often include passing industry-recognized exams such as those from the American Petroleum Institute (API) or equivalent organizations. Continuous education and periodic re-certification ensure operators maintain up-to-date knowledge of evolving technologies and safety standards.

Career Growth and Opportunities for Production Operators in Oil

Production Operators in the oil industry play a crucial role in managing and maintaining the equipment that extracts oil and gas from underground reservoirs. Career growth opportunities include advancing to roles such as Senior Production Operator, Field Supervisor, or Operations Manager, often supported by specialized training and certifications. The expanding global demand for energy fosters steady job availability and the potential for increased responsibility within oil production companies.

Related Important Terms

Digital Twin Integration

Production Operators leverage digital twin integration to monitor real-time asset performance, enabling predictive maintenance and optimizing production efficiency in oil extraction processes. This technology reduces downtime and operational costs by creating accurate virtual replicas of physical systems for enhanced decision-making.

Predictive Maintenance Analytics

Production Operators leverage predictive maintenance analytics to monitor equipment performance and anticipate failures, significantly reducing unplanned downtime and maintenance costs. Integrating real-time sensor data with advanced machine learning models enables early detection of anomalies, optimizing production efficiency in oil extraction and refining processes.

Remote Operations Center (ROC)

A Production Operator at a Remote Operations Center (ROC) leverages advanced monitoring systems and real-time data analytics to optimize oil extraction processes while ensuring safety and efficiency. This role involves coordinating remote equipment controls, troubleshooting operational issues, and maintaining continuous production flow across multiple field locations.

Autonomous Well Surveillance

Production Operators utilize Autonomous Well Surveillance systems to monitor well performance in real-time, ensuring optimal extraction rates and early detection of anomalies. These advanced technologies enable continuous data collection and analysis, significantly reducing downtime and operational costs in oil production.

Edge Computing Deployment

Edge computing deployment in oil production operations enhances real-time data processing and decision-making at the wellsite, reducing latency and operational costs. Production operators leverage edge devices to monitor equipment performance, optimize production workflows, and ensure rapid response to anomalies without reliance on centralized cloud systems.

Production Operator Infographic

jobdayta.com

jobdayta.com