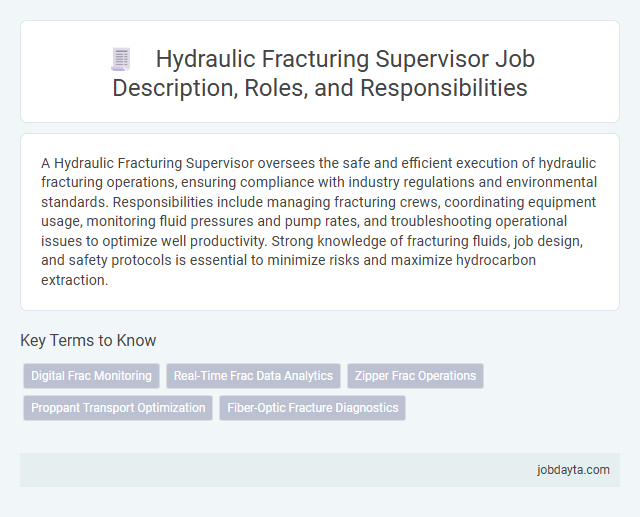

A Hydraulic Fracturing Supervisor oversees the safe and efficient execution of hydraulic fracturing operations, ensuring compliance with industry regulations and environmental standards. Responsibilities include managing fracturing crews, coordinating equipment usage, monitoring fluid pressures and pump rates, and troubleshooting operational issues to optimize well productivity. Strong knowledge of fracturing fluids, job design, and safety protocols is essential to minimize risks and maximize hydrocarbon extraction.

Overview of a Hydraulic Fracturing Supervisor

| Overview of a Hydraulic Fracturing Supervisor | |

|---|---|

| Role | The Hydraulic Fracturing Supervisor oversees the fracturing operations to enhance oil and gas extraction efficiency. This position ensures safe and effective execution of hydraulic fracturing treatments on well sites. |

| Responsibilities | Managing teams, coordinating fracturing fluid preparation, monitoring pressure and flow rates, ensuring compliance with environmental and safety regulations, and troubleshooting operational challenges. |

| Skills Required | In-depth knowledge of hydraulic fracturing techniques, strong leadership, data analysis for optimizing fracture designs, and understanding of wellsite safety protocols. |

| Key Objectives | Maximize hydrocarbon recovery by optimizing fracture treatments while minimizing environmental impact and maintaining operational safety standards. |

| Impact | Effective supervision leads to improved production rates, reduced operational risks, and better resource management within the oil extraction process. |

| Your Role | As a Hydraulic Fracturing Supervisor, you play a central role in coordinating field activities and ensuring that fracturing operations meet technical and safety requirements efficiently. |

Key Responsibilities of a Hydraulic Fracturing Supervisor

What are the key responsibilities of a Hydraulic Fracturing Supervisor in the oil industry? A Hydraulic Fracturing Supervisor oversees the entire fracturing process, ensuring safe and efficient operations. You manage teams and coordinate equipment to optimize well productivity and minimize environmental impact.

How does a Hydraulic Fracturing Supervisor ensure compliance with industry standards? The supervisor monitors operations to adhere to safety protocols and regulatory requirements. They conduct regular inspections and implement corrective actions to maintain compliance and protect personnel.

What role does a Hydraulic Fracturing Supervisor play in project planning and execution? They develop detailed fracturing plans based on geological data and well specifications. Scheduling and resource allocation fall under their purview to ensure project milestones are met on time and within budget.

How is communication critical for a Hydraulic Fracturing Supervisor? Clear communication between field crews, engineers, and management is essential to coordinate activities and address issues promptly. The supervisor serves as the liaison to facilitate information flow and decision-making across teams.

Why is safety management a priority for Hydraulic Fracturing Supervisors? Hydraulic fracturing involves high-pressure equipment and hazardous materials, posing significant risks. Supervisors enforce safety measures, conduct training sessions, and monitor operational conditions to prevent accidents and injuries.

Essential Qualifications and Skills Required

Hydraulic Fracturing Supervisors play a crucial role in managing and overseeing hydraulic fracturing operations in the oil industry. They ensure safe, efficient, and environmentally compliant execution of fracturing processes.

Essential qualifications include a degree in petroleum engineering or a related field, combined with extensive field experience in hydraulic fracturing. Strong knowledge of fracture design, fluid dynamics, and proppant placement techniques is vital. Excellent leadership, communication, and problem-solving skills enable effective team coordination and response to operational challenges.

Daily Tasks and Operational Duties

The Hydraulic Fracturing Supervisor oversees the execution of fracturing operations to enhance oil and gas extraction. This role ensures compliance with safety standards and operational protocols on-site.

Daily tasks include monitoring pressure levels, coordinating with equipment operators, and managing fluid injection rates. The supervisor analyzes real-time data to optimize fracture designs and mitigate risks during operations.

Safety and Environmental Compliance

Hydraulic Fracturing Supervisors play a critical role in managing on-site operations to ensure all safety protocols are strictly followed. Their expertise minimizes risks associated with high-pressure fracturing processes in oil extraction.

Environmental compliance is a key responsibility, involving monitoring emissions and waste to meet regulatory standards. You rely on their vigilance to protect both personnel and surrounding ecosystems during hydraulic fracturing projects.

Team Leadership and Crew Management

Hydraulic Fracturing Supervisors play a crucial role in overseeing the safe and efficient execution of fracturing operations. They ensure that all team members perform their duties according to strict safety and operational standards.

- Leadership Excellence - Directs and motivates fracturing crews to achieve high performance and meet project deadlines.

- Safety Management - Enforces rigorous safety protocols to minimize risks and protect personnel during hydraulic fracturing.

- Crew Coordination - Organizes team tasks and resources to optimize workflow and equipment usage on-site.

Effective team leadership and crew management are essential for successful hydraulic fracturing projects in the oil industry.

Coordination with Engineering and Field Teams

The Hydraulic Fracturing Supervisor plays a critical role in ensuring seamless coordination between engineering and field teams. Efficient communication improves operational performance and safety standards throughout the fracturing process.

- Facilitating Technical Collaboration - You coordinate with engineering teams to align well design parameters with on-site operational capabilities, optimizing fracture stages and resource allocation.

- Monitoring Real-Time Data - The supervisor reviews pressure, flow, and proppant data with engineers to make immediate adjustments that maintain well integrity and maximize production.

- Ensuring Safety Compliance - Collaboration with field teams enforces adherence to safety protocols and environmental regulations during hydraulic fracturing activities, minimizing risks and incidents.

Problem-Solving and Decision-Making in Hydraulic Fracturing

The Hydraulic Fracturing Supervisor plays a critical role in managing complex operational challenges during fracturing processes. Strong problem-solving skills enable the supervisor to quickly identify issues such as equipment malfunctions or pressure anomalies, ensuring minimal downtime. Effective decision-making ensures optimal fracture design and execution, enhancing hydrocarbon recovery and maintaining safety standards.

Tools, Equipment, and Technology Used

Hydraulic Fracturing Supervisors oversee complex operations using cutting-edge tools like blending units, high-pressure pumps, and proppant delivery systems. Advanced monitoring technologies such as real-time data acquisition and pressure sensors ensure optimal fracture placement and operational safety. Your expertise is essential in managing equipment to enhance efficiency and minimize environmental impact during fracturing processes.

Career Path and Advancement Opportunities

A Hydraulic Fracturing Supervisor oversees the safe and efficient execution of fracking operations in oil and gas extraction. This role requires technical expertise and leadership skills to manage teams and ensure compliance with industry standards.

- Entry-Level Roles - Start as a fracturing engineer or field technician to gain hands-on experience in hydraulic fracturing techniques and equipment.

- Mid-Level Advancement - Progress to supervisory roles by developing project management skills and deepening knowledge of fracturing fluid dynamics and well completion.

- Senior Career Opportunities - Move into operations management, consulting, or safety compliance leadership positions with expanded responsibility for multiple sites and teams.

Related Important Terms

Digital Frac Monitoring

Hydraulic Fracturing Supervisors utilize Digital Frac Monitoring technologies to optimize pressure management and proppant placement, ensuring efficient reservoir stimulation and minimizing environmental impact. Advanced real-time data analytics improve decision-making accuracy, enhance well integrity, and reduce operational risks in unconventional oil extraction.

Real-Time Frac Data Analytics

A Hydraulic Fracturing Supervisor leverages real-time frac data analytics to monitor and optimize pressure, fluid flow rates, and proppant placement, ensuring efficient reservoir stimulation and minimizing operational risks. Advanced data visualization and predictive modeling enable rapid decision-making, improving fracture design accuracy and enhancing overall production performance.

Zipper Frac Operations

A Hydraulic Fracturing Supervisor overseeing zipper frac operations ensures synchronized dual-well stimulation to optimize reservoir contact and enhance production rates. Expertise in pressure monitoring, pump scheduling, and communication between fracturing crews maximizes efficiency and minimizes downtime during simultaneous fracturing stages.

Proppant Transport Optimization

Hydraulic fracturing supervisors optimize proppant transport by adjusting slurry viscosity, injection rates, and fracture fluid properties to enhance fracture conductivity and maximize hydrocarbon recovery. Effective proppant placement reduces formation damage and improves fracture complexity, ensuring efficient resource extraction in unconventional reservoirs.

Fiber-Optic Fracture Diagnostics

Hydraulic Fracturing Supervisors leverage fiber-optic fracture diagnostics technology to monitor real-time fracture propagation and optimize hydrocarbon extraction efficiency in unconventional reservoirs. This advanced method enhances fracture mapping accuracy, enabling precise pressure and temperature measurements critical for maximizing well productivity and minimizing environmental impact.

Hydraulic Fracturing Supervisor Infographic

jobdayta.com

jobdayta.com