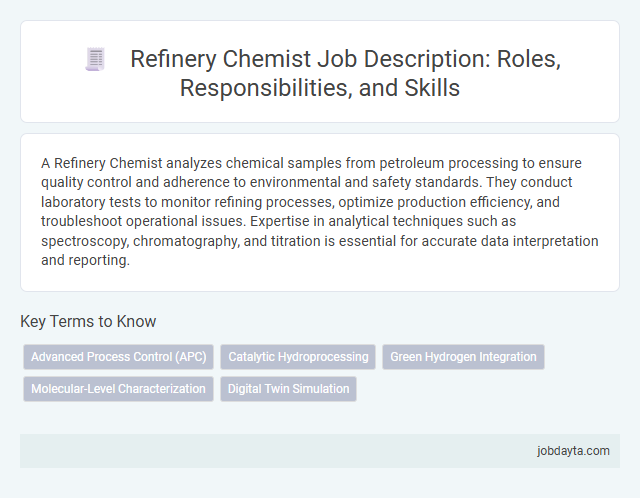

A Refinery Chemist analyzes chemical samples from petroleum processing to ensure quality control and adherence to environmental and safety standards. They conduct laboratory tests to monitor refining processes, optimize production efficiency, and troubleshoot operational issues. Expertise in analytical techniques such as spectroscopy, chromatography, and titration is essential for accurate data interpretation and reporting.

Overview of Refinery Chemist Role

A Refinery Chemist plays a vital role in the petroleum refining industry by analyzing crude oil and refined products to ensure quality and compliance with industry standards. Their expertise supports efficient processing and optimization of refinery operations.

These professionals conduct chemical tests to monitor the composition and properties of feedstocks and finished fuels, identifying contaminants and impurities. They collaborate with engineers to troubleshoot processing issues and recommend adjustments to improve yield and product quality. Proficiency in laboratory instrumentation and knowledge of petroleum chemistry are essential to the Refinery Chemist role.

Key Responsibilities of a Refinery Chemist

| Key Responsibilities of a Refinery Chemist | |

|---|---|

| Sample Analysis | Conducting detailed chemical analyses of crude oil, intermediate products, and finished fuels to ensure quality and compliance with industry standards. |

| Process Monitoring | Monitoring refining processes by analyzing chemical compositions and adjusting parameters to optimize product yield and reduce waste. |

| Quality Control | Implementing rigorous quality control protocols to detect impurities and ensure product specifications meet regulatory and safety requirements. |

| Data Interpretation | Interpreting chemical data from laboratory tests to inform decisions on refining operations and process improvements. |

| Reporting | Preparing accurate reports detailing analytical results, process conditions, and any recommendations for adjustments. |

| Equipment Maintenance | Ensuring laboratory and field instruments are calibrated and maintained for precise chemical measurements. |

| Regulatory Compliance | Assisting in compliance with environmental and safety regulations by monitoring emissions and chemical outputs. |

| Research and Development | Supporting R&D efforts to develop new refining techniques and improve existing chemical processes. |

| Your Role | Maintaining accuracy and reliability in chemical analysis directly impacts refinery efficiency and product quality. |

Essential Skills for Refinery Chemists

Refinery chemists play a critical role in optimizing the chemical processes involved in refining crude oil into valuable petroleum products. Their expertise ensures product quality, process efficiency, and environmental compliance.

Essential skills for refinery chemists include a strong foundation in analytical chemistry techniques such as chromatography and spectroscopy. Proficiency in process control and data interpretation enables them to troubleshoot and improve refinery operations effectively.

Educational Requirements for Refinery Chemists

Refinery chemists play a crucial role in monitoring and improving the chemical processes involved in oil refining. Your educational background must be robust to meet the technical challenges of this field.

- Bachelor's Degree in Chemistry or Chemical Engineering - A relevant undergraduate degree is essential for foundational knowledge in chemical properties and processes used in refineries.

- Advanced Certifications - Specialized certifications in petroleum chemistry or process engineering enhance technical skills and job prospects.

- Practical Laboratory Experience - Hands-on training with analytical instruments and refinery procedures is critical for effective real-world application.

Meeting these educational requirements equips you to ensure refinery operations are efficient and compliant with safety standards.

Daily Tasks and Workflow in Refinery Chemistry

Refinery chemists play a critical role in ensuring the quality and safety of petroleum products through precise chemical analysis and process monitoring. Your expertise supports efficient refinery operations by identifying chemical compositions and optimizing product formulations.

- Sample Collection - Refinery chemists collect samples from various stages of the refining process to analyze chemical properties and detect impurities.

- Chemical Analysis - Conducting detailed laboratory tests, such as chromatography and spectroscopy, helps determine hydrocarbon composition and fuel specifications.

- Process Optimization - Interpreting analytical data allows refinery chemists to recommend adjustments in temperature, pressure, and catalysts for improved yield and efficiency.

Safety and Compliance in Refinery Chemistry

How critical is safety and compliance in refinery chemistry? Ensuring strict adherence to safety protocols minimizes risks associated with hazardous chemicals and high-temperature processes. Your role as a refinery chemist involves continuous monitoring to maintain regulatory compliance and protect both personnel and the environment.

Analytical Techniques Used by Refinery Chemists

Refinery chemists play a crucial role in ensuring the quality and safety of petroleum products through precise chemical analysis. Mastery of various analytical techniques allows you to monitor and optimize refining processes effectively.

- Gas Chromatography (GC) - Separates complex mixtures to identify and quantify hydrocarbons present in refinery samples.

- Atomic Absorption Spectroscopy (AAS) - Detects trace metals in crude oil and refined products to prevent catalyst poisoning and equipment corrosion.

- Fourier Transform Infrared Spectroscopy (FTIR) - Analyzes molecular structures and functional groups to assess product composition and contamination levels.

Career Growth and Opportunities in Refinery Chemistry

Refinery chemists play a crucial role in optimizing the chemical processes involved in petroleum refining, ensuring product quality and process efficiency. Their expertise in analytical techniques and chemical engineering principles drives innovation within refinery operations.

The career growth for refinery chemists includes advanced positions such as process development specialist, quality control manager, and research scientist. Opportunities also extend to roles in environmental compliance and catalyst development, reflecting the industry's evolving focus on sustainability and efficiency.

Challenges Faced by Refinery Chemists

Refinery chemists confront complex challenges in managing the quality and composition of petroleum products to meet stringent industry standards. You must accurately analyze samples using advanced spectroscopic and chromatographic techniques while ensuring safety and environmental compliance. Balancing operational efficiency with regulatory requirements demands continuous adaptation to evolving technologies and raw material variations.

Tools and Technology in Refinery Chemistry

A Refinery Chemist utilizes advanced analytical instruments such as gas chromatographs, mass spectrometers, and atomic absorption spectrometers to monitor and optimize refinery processes. Cutting-edge software tools enable precise data analysis and real-time process control, enhancing product quality and operational efficiency. Innovations in sensor technology and automation continue to drive improvements in refining techniques and environmental compliance.

Related Important Terms

Advanced Process Control (APC)

Refinery chemists leverage Advanced Process Control (APC) technologies to optimize chemical reactions and improve refinery efficiency by monitoring real-time process variables and adjusting operational parameters. Implementing APC enhances hydrocarbon yield, minimizes energy consumption, and ensures compliance with environmental regulations through precise control of refining processes.

Catalytic Hydroprocessing

A Refinery Chemist specializing in Catalytic Hydroprocessing optimizes reaction conditions to enhance the removal of sulfur, nitrogen, and metals from petroleum fractions, improving fuel quality and compliance with environmental regulations. Expertise in catalyst selection, activity monitoring, and process parameter adjustments ensures maximum conversion efficiency and minimal catalyst deactivation.

Green Hydrogen Integration

Refinery chemists play a crucial role in optimizing green hydrogen integration by developing advanced catalytic processes that enhance hydrogen purity and minimize carbon emissions. Their expertise enables refineries to transition towards sustainable energy solutions, improving efficiency and reducing environmental impact.

Molecular-Level Characterization

Refinery chemists utilize advanced molecular-level characterization techniques such as gas chromatography-mass spectrometry (GC-MS) and nuclear magnetic resonance (NMR) spectroscopy to analyze hydrocarbon compositions and detect trace impurities. Precise molecular profiling enables optimization of refining processes, improving catalyst performance and product yield while ensuring compliance with environmental regulations.

Digital Twin Simulation

Refinery chemists leverage digital twin simulation to model and optimize complex chemical processes within refineries, enhancing real-time monitoring and predictive maintenance. Implementing advanced digital twin technology enables improved reaction efficiency, reduced operational risks, and decreased environmental impact in hydrocarbon refining.

Refinery Chemist Infographic

jobdayta.com

jobdayta.com