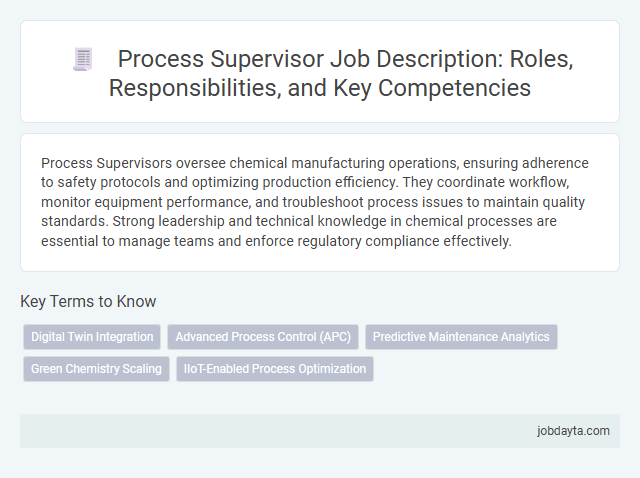

Process Supervisors oversee chemical manufacturing operations, ensuring adherence to safety protocols and optimizing production efficiency. They coordinate workflow, monitor equipment performance, and troubleshoot process issues to maintain quality standards. Strong leadership and technical knowledge in chemical processes are essential to manage teams and enforce regulatory compliance effectively.

Overview of a Process Supervisor in the Chemical Industry

A Process Supervisor in the chemical industry oversees daily operations within manufacturing plants to ensure safety, efficiency, and compliance with regulatory standards. This role involves coordinating teams and managing production processes to maintain product quality and optimize output.

Process Supervisors monitor chemical reactions, control equipment settings, and implement troubleshooting procedures to prevent disruptions. They enforce strict safety protocols to minimize hazards associated with handling hazardous substances and complex machinery. Their expertise supports continuous improvement initiatives and adherence to environmental regulations, contributing to sustainable industrial practices.

Key Roles and Responsibilities of a Process Supervisor

The Process Supervisor plays a crucial role in managing and overseeing chemical production operations to ensure safety, quality, and efficiency. Your leadership directly impacts process optimization and regulatory compliance in chemical plants.

- Oversee Production Processes - Monitor chemical manufacturing activities to maintain consistent output and meet production targets.

- Ensure Safety Compliance - Enforce strict adherence to safety protocols and environmental regulations within the facility.

- Coordinate Team Activities - Manage and guide process operators and technicians to maintain smooth workflow and resolve operational issues.

Effective supervision enhances operational efficiency and minimizes hazards in chemical processing environments.

Essential Skills and Competencies for Process Supervisors

Process Supervisors in the chemical industry play a pivotal role in overseeing production activities and ensuring safety standards. Mastery of technical knowledge and leadership skills is essential for effective process management and team coordination.

- Technical Expertise - In-depth understanding of chemical processes and equipment operation is crucial for maintaining production efficiency and quality control.

- Problem-Solving Skills - Ability to quickly identify and resolve process deviations or equipment malfunctions minimizes downtime and enhances safety.

- Communication Competency - Clear and concise communication with team members and management ensures alignment on operational goals and safety protocols.

Educational and Professional Qualifications Required

A Process Supervisor in the chemical industry typically requires a bachelor's degree in chemical engineering, industrial engineering, or a related field. Professional certifications such as Six Sigma or Lean Manufacturing are highly valued for efficient process management.

You should have several years of hands-on experience in process optimization, safety compliance, and team leadership within a chemical manufacturing environment. Strong knowledge of chemical processes, quality control standards, and regulatory requirements is essential for success in this role.

Daily Tasks and Workflow Management

The role of a Process Supervisor in the chemical industry involves overseeing daily operations to ensure production efficiency and safety compliance. Managing workflow effectively is critical to maintaining continuous process improvement and minimizing downtime.

- Monitor Production Processes - Continuously check equipment and chemical reactions to maintain optimal operating conditions.

- Coordinate Team Activities - Assign and supervise tasks to operators and technicians to meet production targets.

- Ensure Safety Protocols - Enforce strict adherence to safety regulations to prevent accidents and hazardous incidents.

Safety and Compliance Responsibilities

The Process Supervisor plays a crucial role in maintaining strict safety protocols to prevent accidents and ensure a hazard-free chemical manufacturing environment. You are responsible for enforcing regulatory compliance, including OSHA standards and Environmental Protection Agency (EPA) guidelines. Vigilant monitoring of equipment operations and employee adherence to safety procedures safeguards both personnel and product integrity.

Team Leadership and Communication Skills

| Role | Process Supervisor |

|---|---|

| Industry | Chemical Manufacturing |

| Core Competencies | Team Leadership, Communication Skills |

| Team Leadership | Leading cross-functional teams in chemical production environments. Implementing safety protocols and operational standards. Motivating and mentoring technicians and operators to enhance productivity and compliance. Coordinating workflow to optimize chemical process efficiency and minimize downtime. |

| Communication Skills | Facilitating clear communication between production staff, engineering teams, and management. Reporting process performance and safety issues accurately. Conducting training sessions on chemical process procedures. Ensuring documentation of standard operating procedures and compliance records is understood and followed. |

| Impact | Improved process safety, increased team productivity, enhanced operational communication, and reduced process deviations in chemical manufacturing settings. |

Problem-Solving and Decision-Making Abilities

Process supervisors in the chemical industry demonstrate exceptional problem-solving skills by quickly identifying process deviations and implementing effective corrective actions. Their decision-making abilities ensure optimal production efficiency while maintaining strict safety and quality standards. These professionals analyze complex data to anticipate potential issues and make informed choices that minimize downtime and operational risks.

Career Path and Advancement Opportunities

Process Supervisors in the chemical industry play a critical role in overseeing production operations and ensuring safety compliance. Their expertise in managing complex chemical processes positions them for leadership roles within manufacturing and quality control departments.

Career advancement often leads to positions such as Plant Manager, Operations Director, or Technical Specialist. Your skills in process optimization and team management open pathways to higher responsibility and strategic decision-making roles.

Impact of a Process Supervisor on Chemical Plant Efficiency

How does a Process Supervisor influence the efficiency of a chemical plant?

A Process Supervisor plays a critical role in optimizing production workflows and ensuring safety protocols are rigorously followed. Their expertise in monitoring process parameters and coordinating team activities leads to minimized downtime and maximized output quality in chemical manufacturing.

Related Important Terms

Digital Twin Integration

Process Supervisors leverage Digital Twin integration to enhance real-time monitoring and predictive maintenance of chemical production systems. This technology enables precise simulation of plant operations, optimizing efficiency and reducing downtime in complex chemical manufacturing processes.

Advanced Process Control (APC)

Process Supervisors specializing in Advanced Process Control (APC) leverage sophisticated algorithms and real-time data analytics to optimize chemical manufacturing processes, enhancing efficiency and product quality. Their expertise in model predictive control and adaptive control systems enables precise regulation of variables such as temperature, pressure, and flow rates, reducing operational variability and minimizing energy consumption.

Predictive Maintenance Analytics

Process Supervisors in the chemical industry leverage predictive maintenance analytics to monitor equipment performance and anticipate failures, reducing downtime and optimizing operational efficiency. Utilizing real-time data and machine learning algorithms, they identify maintenance needs before breakdowns occur, ensuring continuous production and cost savings.

Green Chemistry Scaling

Process Supervisors in green chemistry scaling ensure the efficient transition of sustainable chemical processes from laboratory to industrial scale while minimizing environmental impact. They optimize resource utilization, enforce safety protocols, and coordinate multidisciplinary teams to enhance process yield and reduce waste generation.

IIoT-Enabled Process Optimization

Process Supervisors leverage IIoT-enabled process optimization to enhance real-time monitoring and control of chemical production systems, resulting in increased operational efficiency and reduced downtime. Advanced sensor networks and data analytics drive predictive maintenance and process automation, ensuring product quality and compliance with safety standards.

Process Supervisor Infographic

jobdayta.com

jobdayta.com