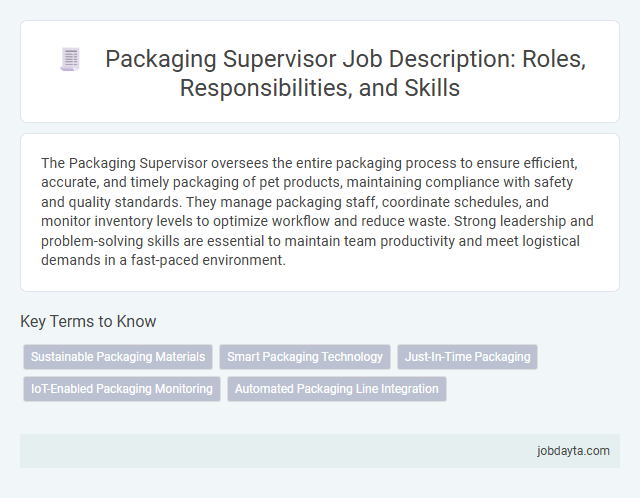

The Packaging Supervisor oversees the entire packaging process to ensure efficient, accurate, and timely packaging of pet products, maintaining compliance with safety and quality standards. They manage packaging staff, coordinate schedules, and monitor inventory levels to optimize workflow and reduce waste. Strong leadership and problem-solving skills are essential to maintain team productivity and meet logistical demands in a fast-paced environment.

Overview of a Packaging Supervisor Role in Logistics

| Overview of a Packaging Supervisor Role in Logistics | |

|---|---|

| Position Title | Packaging Supervisor |

| Primary Responsibility | Overseeing the packaging operations within a logistics environment to ensure efficiency, safety, and quality compliance. |

| Key Duties |

|

| Essential Skills | Leadership, logistics coordination, quality control, problem-solving, time management, and effective communication. |

| Impact on Operations | Your leadership ensures streamlined packaging processes that reduce damages, lower costs, and improve customer satisfaction within the supply chain. |

| Industry Relevance | Critical for logistics companies, manufacturing plants, and distribution centers where packaging integrity directly affects shipments and inventory turnover. |

Key Responsibilities of a Packaging Supervisor

The Packaging Supervisor oversees all packaging operations, ensuring products are packed efficiently and meet quality standards. They coordinate with production and warehouse teams to streamline workflows and reduce packaging errors.

They manage packaging materials inventory to prevent delays and minimize waste. The role involves training staff on proper packaging techniques and safety protocols to maintain compliance and productivity.

Essential Skills for Effective Packaging Supervision

Effective Packaging Supervisors must possess strong organizational skills to manage workflows and ensure timely deliveries. Attention to detail is crucial for maintaining packaging quality and compliance with safety standards. You also need excellent communication abilities to coordinate teams and streamline operations efficiently.

Daily Tasks and Duties of a Packaging Supervisor

The Packaging Supervisor oversees all packaging operations to ensure efficiency and quality standards are met. They coordinate with the production team to maintain smooth workflow and timely delivery of packaged goods.

Daily tasks include monitoring packaging line performance, inspecting finished products for compliance with safety and quality regulations, and managing packaging staff schedules. The supervisor trains team members on proper packaging techniques and safety protocols. They also troubleshoot issues on the packaging floor to minimize downtime and improve productivity.

Packaging Supervisor’s Role in Quality Control

How does a Packaging Supervisor ensure quality control in logistics? A Packaging Supervisor implements rigorous inspection protocols to maintain packaging standards throughout the supply chain. They monitor materials, processes, and final packaging to prevent damages and ensure compliance with safety regulations.

Leadership and Team Management in Packaging Supervision

The Packaging Supervisor plays a critical role in leading teams to ensure efficient and compliant packaging processes. Your leadership directly impacts productivity and quality within the logistics chain.

- Effective Team Leadership - Motivates and guides packaging staff to meet operational goals with precision and safety.

- Performance Management - Monitors team performance and implements improvements to enhance output and reduce errors.

- Training and Development - Provides ongoing coaching to build skills and maintain high standards in packaging procedures.

Safety and Compliance Responsibilities in Packaging

The Packaging Supervisor ensures all packaging processes comply with industry safety standards and regulatory requirements. They conduct regular audits to identify and address potential hazards in the packaging area.

Your role involves training the packaging team on proper safety protocols and the correct use of protective equipment. Maintaining detailed compliance records helps guarantee consistent adherence to legal and company policies.

Tools and Technologies Used by Packaging Supervisors

Packaging Supervisors utilize advanced tools and technologies to ensure efficient packaging processes and maintain product quality. These tools enhance accuracy, speed, and safety in logistics operations.

- Automated Packaging Machines - These machines increase packaging speed and consistency while reducing manual labor.

- Barcode Scanners and RFID Technology - Used for real-time tracking and inventory management during packaging and shipment.

- Packaging Design Software - Enables creation of optimized packaging layouts that minimize material use and protect products effectively.

Challenges Faced by Packaging Supervisors in Logistics

Packaging supervisors in logistics oversee the efficient and secure packing of goods to ensure timely delivery. They face multiple challenges that impact operational efficiency and product safety.

- Managing Packaging Quality - Ensuring consistent packaging standards to prevent damage during transit requires meticulous oversight and quality control.

- Coordination with Supply Chain - Aligning packaging schedules with supply chain demands is critical to avoid delays and bottlenecks.

- Adapting to Regulatory Compliance - Navigating complex packaging regulations and environmental guidelines demands constant updates and training.

Overcoming these challenges is essential for maintaining smooth logistics operations and customer satisfaction.

Career Path and Advancement Opportunities for Packaging Supervisors

Packaging Supervisors play a crucial role in overseeing the packaging process, ensuring products meet quality and safety standards. Career advancement often leads to roles such as Logistics Manager, Operations Manager, or Supply Chain Coordinator, expanding leadership responsibilities. Gaining expertise in lean manufacturing and supply chain technology enhances promotion prospects within the logistics industry.

Related Important Terms

Sustainable Packaging Materials

Packaging Supervisors oversee the implementation of sustainable packaging materials, ensuring compliance with environmental regulations and optimizing resource efficiency throughout the supply chain. Their expertise in biodegradable, recyclable, and reduced-waste materials significantly contributes to cost savings and corporate sustainability goals.

Smart Packaging Technology

A Packaging Supervisor leverages smart packaging technology to enhance supply chain efficiency by integrating IoT sensors and RFID tags that monitor product conditions in real-time. Implementing automated tracking systems reduces errors and improves inventory accuracy, driving significant cost savings in logistics operations.

Just-In-Time Packaging

A Packaging Supervisor specializing in Just-In-Time (JIT) packaging ensures seamless coordination between inventory management and production schedules to minimize waste and reduce storage costs. Expertise in JIT packaging enhances supply chain efficiency by delivering materials precisely when needed, optimizing workflow and improving overall product turnaround time.

IoT-Enabled Packaging Monitoring

IoT-enabled packaging monitoring empowers packaging supervisors to track real-time conditions such as temperature, humidity, and tampering risks throughout the supply chain, ensuring product integrity and reducing spoilage. Integrating sensors and cloud-based analytics facilitates proactive decision-making, enhances compliance with safety standards, and optimizes packaging processes efficiently.

Automated Packaging Line Integration

The Packaging Supervisor oversees the seamless integration of automated packaging line systems, optimizing workflow efficiency and ensuring compliance with safety and quality standards. Expertise in coordinating robotics, conveyor systems, and software controls reduces downtime while enhancing packaging speed and accuracy in logistics operations.

Packaging Supervisor Infographic

jobdayta.com

jobdayta.com