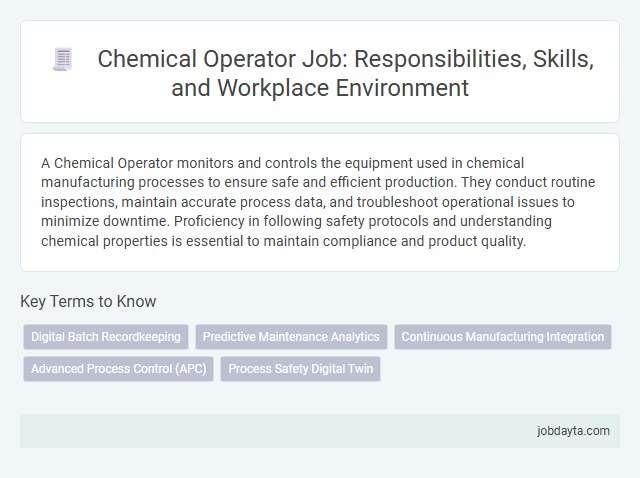

A Chemical Operator monitors and controls the equipment used in chemical manufacturing processes to ensure safe and efficient production. They conduct routine inspections, maintain accurate process data, and troubleshoot operational issues to minimize downtime. Proficiency in following safety protocols and understanding chemical properties is essential to maintain compliance and product quality.

Overview of a Chemical Operator Role

A Chemical Operator plays a crucial role in managing and monitoring chemical processes within industrial plants. This position ensures the safe and efficient production of chemicals by controlling equipment and systems.

- Process Monitoring - Oversees chemical reactions and process variables to maintain product quality and safety standards.

- Equipment Operation - Operates pumps, valves, and reactors to facilitate continuous chemical production.

- Safety Compliance - Adheres to strict safety protocols to prevent hazardous incidents and environmental contamination.

Key Responsibilities of a Chemical Operator

A Chemical Operator controls and monitors chemical processes to ensure safe and efficient production. Key responsibilities include operating equipment, maintaining process parameters, and conducting quality checks on raw materials and finished products. You are also responsible for adhering to safety regulations and troubleshooting any process deviations promptly.

Essential Skills for Chemical Operators

Chemical operators play a critical role in managing and controlling chemical processes in industrial settings. Mastery of essential skills ensures operational safety, efficiency, and regulatory compliance.

- Technical Knowledge - Understanding chemical processes, equipment, and safety protocols is vital for effective operation and troubleshooting.

- Attention to Detail - Precise monitoring and adjustment of process variables prevent errors and potential hazards.

- Problem-Solving Skills - Ability to quickly identify and resolve operational issues maintains continuous production and safety standards.

Safety Protocols in Chemical Operations

Chemical operators play a critical role in maintaining safety protocols to prevent accidents and ensure operational efficiency. Strict adherence to safety guidelines minimizes exposure to hazardous substances and reduces the risk of chemical spills.

Personal protective equipment (PPE) such as gloves, goggles, and respirators are essential in safeguarding workers from toxic materials. Regular training on emergency response and proper chemical handling reinforces a culture of safety within chemical plants.

Daily Tasks and Workflow of Chemical Operators

What are the primary daily tasks of a chemical operator? Chemical operators monitor and control chemical processes to ensure optimal production quality. They conduct routine inspections, adjust equipment settings, and maintain safety standards throughout their shifts.

How does the workflow of chemical operators typically proceed? Operators start by reviewing process parameters and equipment status, followed by managing material inputs and outputs. Continuous monitoring and timely reporting of system performance are essential for maintaining efficient operations.

Required Educational and Certification Qualifications

| Required Educational Qualifications |

|

|---|---|

| Certification Qualifications |

|

Tools and Equipment Used by Chemical Operators

Chemical operators utilize specialized tools and equipment to ensure safe and efficient chemical processing. These tools are essential for monitoring, controlling, and maintaining chemical production plants.

- Pressure Gauges - Used to monitor the pressure levels within reactors and pipelines, ensuring operations remain within safe limits.

- Flow Meters - Measure the flow rate of liquids and gases to maintain precise control over chemical processes.

- Personal Protective Equipment (PPE) - Includes gloves, goggles, and respirators to protect operators from hazardous substances.

Proper use of these tools and equipment is critical for maintaining safety and optimizing chemical production efficiency.

Common Challenges Faced by Chemical Operators

Chemical operators often face challenges related to equipment malfunctions and unexpected process deviations. These issues can disrupt production schedules and affect product quality.

Handling hazardous materials requires strict adherence to safety protocols to prevent accidents and exposure. Operators must continuously monitor systems and adjust operations to maintain optimal conditions.

Workplace Environment and Conditions in Chemical Plants

Chemical operators work in highly controlled environments within chemical plants, where safety protocols and strict regulations are essential. The workplace often involves exposure to hazardous substances, requiring the use of personal protective equipment (PPE) and constant monitoring of chemical processes. Your role demands attention to detail and adherence to safety standards to maintain a secure and efficient plant operation.

Career Growth and Opportunities for Chemical Operators

Chemical operators play a critical role in managing and monitoring industrial chemical processes. Their expertise ensures safety, efficiency, and compliance within manufacturing environments.

Career growth for chemical operators is promising, with opportunities to advance into supervisory or technical specialist roles. Continuous training and certification in process technology and safety protocols enhance job prospects. Industries such as pharmaceuticals, petrochemicals, and food processing frequently seek skilled operators, expanding employment potential.

Related Important Terms

Digital Batch Recordkeeping

Chemical Operators leveraging Digital Batch Recordkeeping enhance process accuracy and traceability by automating data capture and real-time monitoring during production. This digital transformation reduces human error, ensures regulatory compliance, and facilitates faster troubleshooting in chemical manufacturing.

Predictive Maintenance Analytics

Chemical operators utilize predictive maintenance analytics to monitor equipment conditions through real-time data analysis, reducing downtime and preventing costly failures in production processes. Advanced sensors and machine learning algorithms enable early detection of anomalies, optimizing operational efficiency and safety in chemical plants.

Continuous Manufacturing Integration

Chemical Operators play a crucial role in Continuous Manufacturing Integration by overseeing real-time process controls and ensuring seamless operation of automated systems, which enhances production efficiency and product consistency. Their expertise in monitoring reaction conditions, adjusting flow rates, and managing instrumentation directly supports uninterrupted chemical synthesis and scalability in industrial settings.

Advanced Process Control (APC)

Chemical Operators leverage Advanced Process Control (APC) systems to enhance process efficiency, ensuring precise regulation of temperature, pressure, and flow rates in complex chemical reactions. By utilizing real-time data analytics and predictive algorithms, APC minimizes operational variability, reduces energy consumption, and improves product quality in industrial chemical manufacturing.

Process Safety Digital Twin

Chemical operators utilize Process Safety Digital Twins to simulate and monitor plant operations in real-time, enhancing hazard detection and risk mitigation. This technology enables predictive maintenance and operational optimization by replicating physical processes with high-fidelity digital models.

Chemical Operator Infographic

jobdayta.com

jobdayta.com