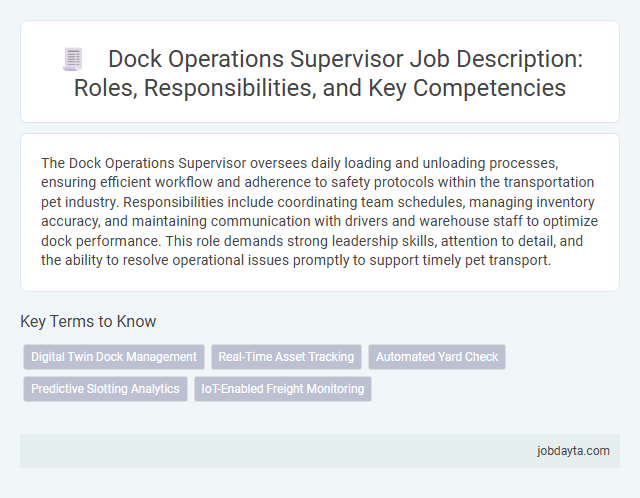

The Dock Operations Supervisor oversees daily loading and unloading processes, ensuring efficient workflow and adherence to safety protocols within the transportation pet industry. Responsibilities include coordinating team schedules, managing inventory accuracy, and maintaining communication with drivers and warehouse staff to optimize dock performance. This role demands strong leadership skills, attention to detail, and the ability to resolve operational issues promptly to support timely pet transport.

Overview of Dock Operations Supervisor Role

The Dock Operations Supervisor oversees the daily activities at loading docks, ensuring efficient and safe handling of incoming and outgoing shipments. This role coordinates with warehouse staff, drivers, and logistics teams to maintain smooth operations.

Key responsibilities include managing dock schedules, verifying shipment accuracy, and enforcing safety protocols. The supervisor plays a critical role in minimizing delays and optimizing dock resources to support overall supply chain performance.

Key Responsibilities of a Dock Operations Supervisor

The Dock Operations Supervisor coordinates daily activities at the shipping and receiving dock to ensure smooth and efficient operations. You manage personnel, equipment, and schedules to meet productivity and safety standards.

- Manage Dock Personnel - Supervise and schedule dock workers to optimize workflow and maintain staffing levels.

- Oversee Cargo Handling - Ensure accurate loading, unloading, and proper storage of goods to prevent damage and delays.

- Maintain Safety Compliance - Enforce safety protocols and conduct regular inspections to reduce accidents and hazards.

Essential Skills and Competencies Required

Dock Operations Supervisors require strong leadership and organizational skills to manage daily activities efficiently. Expertise in logistics coordination and safety compliance ensures smooth operations at the dock.

Your ability to communicate clearly and solve problems quickly is essential for supervising teams and handling unexpected challenges. Proficiency in inventory management systems and equipment operation enhances productivity and reduces errors. Time management and attention to detail are critical to maintaining workflows and meeting shipping deadlines.

Managing Loading and Unloading Processes

The Dock Operations Supervisor oversees the efficient management of loading and unloading processes to ensure timely shipment and receipt of goods. This role involves coordinating with warehouse staff and transportation teams to optimize dock space utilization and minimize turnaround times. Effective supervision of these processes reduces delays, enhances safety, and improves overall supply chain performance.

Ensuring Safety and Compliance in Dock Operations

| Role | Dock Operations Supervisor |

|---|---|

| Primary Focus | Ensuring Safety and Compliance in Dock Operations |

| Key Responsibilities |

|

| Safety Measures |

|

| Compliance Standards |

|

| Performance Metrics |

|

Coordination with Supply Chain and Logistics Teams

The Dock Operations Supervisor plays a crucial role in ensuring seamless coordination between dock activities and supply chain processes. Effective collaboration with logistics teams enhances shipment accuracy and timely distribution.

- Facilitates Communication - Acts as the primary liaison between dock personnel and supply chain managers to align receiving and shipping schedules.

- Optimizes Workflow - Coordinates loading and unloading operations to match inventory management and transportation plans.

- Monitors Performance - Tracks dock operations metrics to support logistics efficiency and improve supply chain responsiveness.

Supervising Dock Staff and Team Leadership

The Dock Operations Supervisor oversees daily activities on the dock, ensuring efficient loading and unloading processes. Supervising dock staff involves assigning tasks, monitoring performance, and maintaining safety compliance. Effective team leadership fosters communication, boosts morale, and drives operational productivity in transportation logistics.

Handling Equipment and Maintenance Oversight

The Dock Operations Supervisor plays a critical role in managing handling equipment to ensure efficient loading and unloading processes. They oversee maintenance activities to maximize equipment uptime and safety compliance.

- Handling Equipment Management - Coordinates the use of forklifts, conveyors, and pallet jacks to streamline cargo movement.

- Maintenance Oversight - Schedules regular inspections and repairs to prevent equipment downtime and operational delays.

- Safety Compliance - Enforces safety protocols related to equipment handling to protect staff and cargo integrity.

The Dock Operations Supervisor ensures smooth dock workflows through effective equipment handling and proactive maintenance strategies.

Utilizing Technology in Dock Operations Management

Dock Operations Supervisors employ advanced technology to streamline loading and unloading processes, enhancing efficiency and reducing turnaround times. Implementing automated scheduling systems enables precise coordination of dock activities, minimizing delays and resource conflicts.

Use of real-time tracking tools allows supervisors to monitor shipments and equipment status, ensuring timely response to operational issues. Integration of data analytics supports informed decision-making, optimizing labor allocation and improving overall dock performance.

Career Path and Advancement Opportunities for Supervisors

What career path can a Dock Operations Supervisor expect in the transportation industry? Dock Operations Supervisors often start as dock workers or shipping coordinators before advancing into supervisory roles. With experience, they can progress to positions such as Logistics Manager or Operations Manager, overseeing broader transportation and supply chain functions.

How do advancement opportunities develop for Dock Operations Supervisors? Growth depends on gaining skills in team leadership, safety compliance, and inventory management. Professionals who demonstrate strong organizational and communication abilities may move into higher management roles or specialize in areas like freight coordination or warehouse operations.

Related Important Terms

Digital Twin Dock Management

A Dock Operations Supervisor leveraging Digital Twin Dock Management enhances efficiency by creating real-time virtual replicas of dock activities to optimize workflow and resource allocation. This technology enables predictive maintenance, reduces downtime, and improves safety by simulating different operational scenarios before implementation.

Real-Time Asset Tracking

A Dock Operations Supervisor leverages real-time asset tracking to enhance inventory accuracy, streamline loading processes, and minimize delays in shipment dispatch. Implementing RFID and GPS technologies enables immediate visibility of cargo locations, improving operational efficiency and reducing the risk of loss or misplacement.

Automated Yard Check

The Dock Operations Supervisor oversees automated yard check systems to enhance efficiency, accuracy, and safety in vehicle tracking and gate management. Implementing RFID technology and real-time data analytics streamlines cargo flow and reduces manual errors in yard operations.

Predictive Slotting Analytics

Dock Operations Supervisors leverage predictive slotting analytics to optimize dock scheduling and improve turnaround times by forecasting shipment arrivals and resource needs. Implementing data-driven slot assignments reduces congestion, enhances loading efficiency, and increases overall supply chain throughput.

IoT-Enabled Freight Monitoring

A Dock Operations Supervisor leverages IoT-enabled freight monitoring systems to enhance real-time tracking, optimize loading efficiency, and reduce shipment errors in dock management. Integrating IoT sensors and RFID technology improves inventory accuracy and streamlines communication between logistics teams, ensuring timely freight movement and minimizing operational downtime.

Dock Operations Supervisor Infographic

jobdayta.com

jobdayta.com