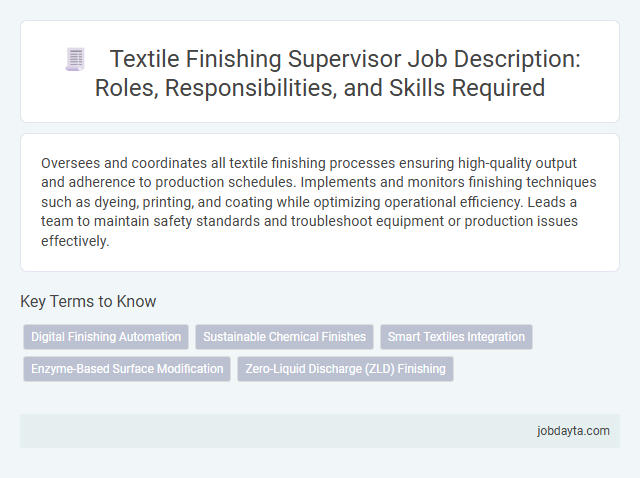

Oversees and coordinates all textile finishing processes ensuring high-quality output and adherence to production schedules. Implements and monitors finishing techniques such as dyeing, printing, and coating while optimizing operational efficiency. Leads a team to maintain safety standards and troubleshoot equipment or production issues effectively.

Overview of Textile Finishing Supervisor Role

The Textile Finishing Supervisor oversees the final stage of textile production, ensuring fabric quality meets industry standards. This role manages the application of processes like dyeing, printing, and coating to enhance fabric appearance and performance.

They coordinate finishing operations, supervise staff, and maintain equipment to optimize productivity. The supervisor also implements quality control measures to detect defects and ensure compliance with customer specifications.

Key Responsibilities of a Textile Finishing Supervisor

The role of a Textile Finishing Supervisor is crucial for ensuring high-quality fabric finishes that meet industry standards. Your expertise directs the finishing process to enhance textile appearance and performance.

- Oversee finishing operations - Manage and monitor fabric treatments such as bleaching, dyeing, and coating to achieve desired fabric qualities.

- Ensure quality control - Conduct inspections and tests to maintain consistent fabric texture, color fastness, and durability throughout finishing.

- Coordinate team activities - Supervise finishing staff and schedule workflows to optimize productivity while adhering to safety protocols.

Essential Skills for Textile Finishing Supervisors

| Essential Skills for Textile Finishing Supervisors |

|---|

You play a critical role in ensuring the final textile products achieve the desired quality and finishing standards, making these essential skills key to your success. |

Day-to-Day Tasks in Textile Finishing Supervision

The Textile Finishing Supervisor plays a crucial role in managing the final stages of fabric production. Your focus lies in ensuring quality, efficiency, and safety during the finishing processes.

- Monitor Finishing Operations - Oversee all finishing activities including washing, bleaching, dyeing, and calendaring to maintain product standards.

- Manage Equipment Maintenance - Coordinate regular inspections and repairs of finishing machinery to avoid production delays.

- Implement Quality Control - Conduct routine quality checks and enforce compliance with industry regulations to guarantee fabric consistency.

Effective supervision in textile finishing directly impacts fabric durability and overall customer satisfaction.

Importance of Quality Control in Textile Finishing

Textile finishing plays a critical role in enhancing fabric appearance and durability. Quality control ensures that finished textiles meet industry standards and customer expectations.

As a Textile Finishing Supervisor, your focus on quality control directly impacts product consistency and performance. Rigorous inspection and testing prevent defects and reduce waste, improving overall efficiency. Maintaining strict quality standards safeguards your company's reputation and drives customer satisfaction.

Managing Textile Finishing Teams Effectively

The Textile Finishing Supervisor plays a crucial role in overseeing the entire finishing process to ensure high-quality fabric output. Effective management of textile finishing teams involves coordinating workflow, maintaining equipment, and enforcing safety standards. Strong leadership and communication skills are essential to optimize productivity and meet production deadlines consistently.

Safety Protocols for Textile Finishing Supervisors

Textile Finishing Supervisors play a critical role in ensuring the safe operation of finishing equipment and processes. They enforce strict safety protocols to minimize hazards associated with chemical treatments and heat applications.

Supervisors train staff on the proper use of personal protective equipment (PPE) to prevent exposure to toxic substances. Regular safety audits and emergency response drills are essential components of their responsibilities to maintain a secure work environment.

Technical Knowledge Required in Textile Finishing

A Textile Finishing Supervisor must possess in-depth technical knowledge of fabric treatment processes including bleaching, dyeing, printing, and coating. Understanding the chemical properties and interactions that affect fabric quality is essential for optimizing finishing results. Your expertise in machinery operation, quality control, and environmental compliance ensures efficient production and superior textile finish.

Career Path and Growth Opportunities for Supervisors

What career path can a Textile Finishing Supervisor expect? A Textile Finishing Supervisor can advance to senior supervisory roles or management positions within production and quality control departments. Opportunities include becoming a Production Manager, Quality Assurance Manager, or Operations Manager in textile manufacturing companies.

How do growth opportunities benefit Textile Finishing Supervisors? Growth opportunities enable supervisors to develop technical expertise and leadership skills critical for overseeing complex finishing processes. Skilled supervisors often receive higher salaries and greater responsibilities in optimizing fabric quality and production efficiency.

Challenges Faced by Textile Finishing Supervisors

Textile finishing supervisors play a critical role in ensuring fabric quality and meeting production deadlines. Managing the finishing process involves navigating numerous operational and technical challenges that impact overall efficiency.

- Maintaining Consistent Quality - Supervisors must ensure uniformity in texture, color, and durability despite variations in raw materials and environmental conditions.

- Equipment Malfunctions - Frequent breakdowns of finishing machines can disrupt workflow and delay delivery schedules.

- Adapting to New Technologies - Staying updated with the latest finishing techniques and machinery requires continuous learning and process adjustments.

- Managing Workforce Efficiency - Coordinating skill levels and productivity of the finishing team is essential for meeting production targets.

- Meeting Environmental Regulations - Supervisors must implement eco-friendly processes while maintaining product quality and operational cost-effectiveness.

Related Important Terms

Digital Finishing Automation

A Textile Finishing Supervisor specializing in Digital Finishing Automation leverages advanced digital technologies to enhance fabric quality and production efficiency in textile finishing processes. Expertise in integrating automated systems such as digital printing, coating, and inspection ensures consistent output while reducing manual errors and operational costs.

Sustainable Chemical Finishes

A Textile Finishing Supervisor specializing in sustainable chemical finishes ensures the application of eco-friendly treatments that reduce environmental impact while enhancing fabric durability and aesthetic appeal. Their expertise in selecting bio-based finishes and managing low-impact processes drives innovation in sustainable textile production and compliance with environmental regulations.

Smart Textiles Integration

A Textile Finishing Supervisor specializing in Smart Textiles Integration oversees the application of advanced coatings, conductive inks, and embedded sensors to enhance fabric functionality and durability. They coordinate production workflows ensuring seamless integration of electronic components with traditional finishing processes to deliver innovative, high-performance textile products.

Enzyme-Based Surface Modification

Enzyme-Based Surface Modification in textile finishing utilizes biocatalysts such as cellulases and laccases to enhance fabric properties like softness, color brightness, and hydrophilicity while reducing chemical usage and environmental impact. A Textile Finishing Supervisor oversees these enzyme applications, ensuring optimal process parameters and quality control to achieve consistent and sustainable fabric enhancements.

Zero-Liquid Discharge (ZLD) Finishing

A Textile Finishing Supervisor specializing in Zero-Liquid Discharge (ZLD) Finishing oversees sustainable processes that eliminate wastewater discharge by recycling and reusing water within textile treatment cycles. They ensure compliance with environmental regulations while optimizing dyeing, washing, and chemical application to enhance fabric quality and reduce ecological impact.

Textile Finishing Supervisor Infographic

jobdayta.com

jobdayta.com