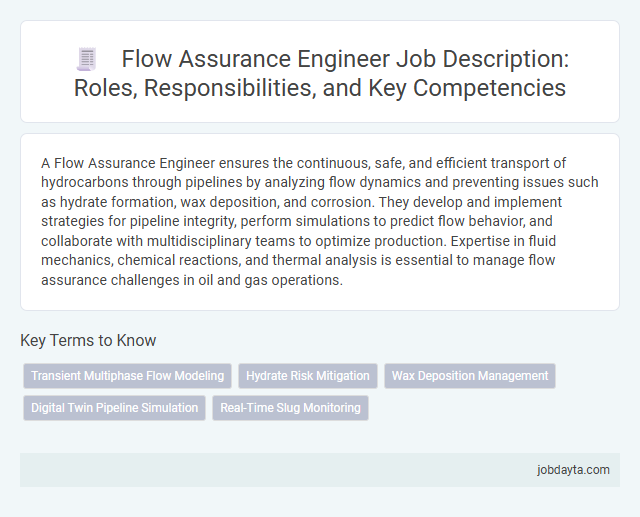

A Flow Assurance Engineer ensures the continuous, safe, and efficient transport of hydrocarbons through pipelines by analyzing flow dynamics and preventing issues such as hydrate formation, wax deposition, and corrosion. They develop and implement strategies for pipeline integrity, perform simulations to predict flow behavior, and collaborate with multidisciplinary teams to optimize production. Expertise in fluid mechanics, chemical reactions, and thermal analysis is essential to manage flow assurance challenges in oil and gas operations.

Introduction to Flow Assurance Engineering in Oil Industry

| Role | Flow Assurance Engineer |

|---|---|

| Industry | Oil and Gas |

| Definition | Flow Assurance Engineering involves ensuring the uninterrupted and safe flow of hydrocarbons from reservoir to processing facilities. |

| Key Responsibilities |

|

| Main Challenges |

|

| Essential Skills |

|

| Industry Impact | Flow assurance engineering maximizes production efficiency, reduces operational downtime, and minimizes environmental risks in oil extraction and transportation. |

Key Roles of a Flow Assurance Engineer

A Flow Assurance Engineer ensures the uninterrupted flow of oil and gas from reservoir to processing facilities. You analyze and mitigate risks related to flow blockages and equipment failures.

Key roles of a Flow Assurance Engineer include evaluating hydrate formation, wax deposition, and corrosion control. You design and implement strategies to prevent flow stoppages and optimize pipeline performance. Monitoring pressure, temperature, and chemical levels forms a crucial part of your responsibilities.

Essential Responsibilities in Flow Assurance Management

Flow Assurance Engineers play a critical role in ensuring the uninterrupted transport of hydrocarbons through pipelines and subsea systems. You are responsible for preventing blockages and optimizing flow conditions to maintain production efficiency.

- Monitoring Fluid Properties - Analyze temperature, pressure, and composition data to predict and mitigate risks such as wax, hydrate, and scale formation.

- Designing Thermal Management Solutions - Develop insulation and heating strategies to maintain adequate fluid temperatures and prevent solid deposition.

- Collaborating with Cross-Disciplinary Teams - Work closely with reservoir, production, and pipeline engineers to optimize overall system performance and safety.

Core Competencies for Flow Assurance Engineers

Flow Assurance Engineers play a critical role in ensuring the uninterrupted transport of hydrocarbons from reservoirs to processing facilities. Core competencies include understanding phase behavior, hydrate formation, and wax deposition within pipelines.

Expertise in multiphase flow dynamics and thermal hydraulic modeling is essential for predicting and mitigating flow interruption risks. Your ability to apply industry standards and integrate advanced simulation software strengthens asset integrity and production efficiency.

Flow Assurance Challenges in Oil Production Systems

Flow Assurance Engineers address critical challenges in oil production systems by preventing blockages caused by hydrates, wax, and asphaltenes. Managing temperature and pressure variations ensures steady fluid flow throughout pipelines and processing facilities. Your expertise helps maintain system integrity and optimize production efficiency under complex subsea conditions.

Technical Skills Required for Flow Assurance Engineers

What technical skills are essential for a Flow Assurance Engineer in the oil industry? Mastery of multiphase flow simulation software such as OLGA and PIPESIM is crucial. Expertise in thermal hydraulic analysis and knowledge of hydrate, wax, and scale management technologies ensures pipeline integrity and production efficiency.

Importance of Flow Assurance in Oil and Gas Projects

Flow assurance is critical for maintaining uninterrupted production in oil and gas projects. It ensures the efficient transport of hydrocarbons from the reservoir to processing facilities without blockages or operational failures.

- Prevention of Blockages - Flow assurance engineers identify and mitigate risks like hydrate formation and wax deposition that can clog pipelines.

- Optimized Production - Effective flow assurance strategies maximize hydrocarbon recovery and minimize production downtime.

- Safety and Environmental Protection - Proper flow management reduces the risk of leaks, spills, and accidents, protecting personnel and the environment.

Tools and Technologies Used by Flow Assurance Engineers

Flow Assurance Engineers utilize advanced simulation software to analyze fluid dynamics and prevent blockages in pipelines. Tools such as OLGA and Pipesim enable accurate modeling of multiphase flow behaviors under various temperature and pressure conditions.

Your role requires proficiency in data acquisition systems and real-time monitoring technologies to detect hydrate formation and wax deposition early. Technologies like fiber optic sensors and thermal insulation materials play a critical part in maintaining flow integrity throughout production.

Career Path and Growth Opportunities in Flow Assurance

Flow Assurance Engineers play a critical role in the oil industry by ensuring the efficient and safe transport of hydrocarbons from reservoir to processing facilities. Career paths in flow assurance typically start with a junior engineer role, advancing to senior engineer, specialist, and managerial positions, often requiring expertise in thermodynamics, fluid mechanics, and pipeline integrity. Growth opportunities include specialization in hydrate management, wax deposition, or multiphase flow simulation, with prospects to lead multidisciplinary teams or contribute to technological innovation in subsea and deepwater projects.

Best Practices for Effective Flow Assurance Engineering

Flow assurance engineering plays a critical role in maintaining the efficient and safe transport of hydrocarbons in oil and gas production. It addresses challenges like hydrate formation, wax deposition, and corrosion to prevent pipeline blockages and equipment failure.

- Comprehensive Risk Analysis - Identify potential flow assurance issues early by assessing operating conditions and fluid properties to mitigate risks effectively.

- Advanced Modeling Techniques - Utilize simulation tools to predict hydrate formation and wax buildup, enabling proactive intervention strategies.

- Regular Monitoring and Maintenance - Implement continuous monitoring systems and scheduled maintenance to ensure pipeline integrity and performance.

Adopting these best practices helps you optimize flow assurance and safeguard your oil transport infrastructure.

Related Important Terms

Transient Multiphase Flow Modeling

Flow Assurance Engineers specializing in Transient Multiphase Flow Modeling utilize advanced simulation software to predict and manage the dynamic behavior of oil, gas, and water mixtures within pipelines, preventing blockages and ensuring steady production. Their expertise in phase transition dynamics and pressure fluctuation analysis is critical for optimizing pipeline design and operational safety in upstream and subsea oil extraction environments.

Hydrate Risk Mitigation

A Flow Assurance Engineer specializing in hydrate risk mitigation employs advanced modeling techniques and real-time monitoring to predict and prevent hydrate formation in subsea pipelines, ensuring uninterrupted hydrocarbon flow. Implementing chemical injection strategies and thermal insulation solutions minimizes blockages, optimizing production efficiency and asset integrity in deepwater oil operations.

Wax Deposition Management

Flow assurance engineers specializing in wax deposition management optimize pipeline integrity by implementing advanced thermal insulation and chemical injection strategies to prevent wax buildup. They utilize real-time monitoring and predictive modeling to mitigate flow restrictions, ensuring continuous hydrocarbon transport and reducing maintenance costs.

Digital Twin Pipeline Simulation

Flow Assurance Engineers utilize Digital Twin Pipeline Simulation to predict and mitigate risks such as hydrate formation, wax deposition, and corrosion in oil pipelines. This advanced technology enables real-time monitoring and optimization of flow dynamics, ensuring pipeline integrity and reducing operational downtime.

Real-Time Slug Monitoring

Flow Assurance Engineers specialize in real-time slug monitoring to detect and mitigate transient multiphase flow instabilities that can compromise pipeline integrity and production efficiency in oil transportation systems. Utilizing advanced sensors and predictive analytics, these engineers optimize flow stability, reduce operational risks, and enhance the reliability of subsea and onshore pipeline networks.

Flow Assurance Engineer Infographic

jobdayta.com

jobdayta.com