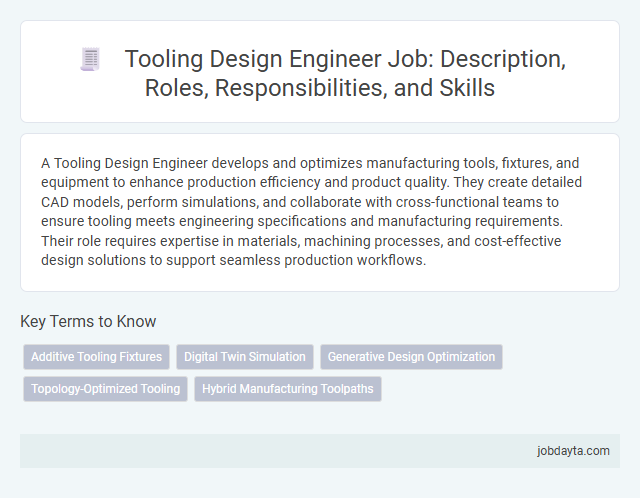

A Tooling Design Engineer develops and optimizes manufacturing tools, fixtures, and equipment to enhance production efficiency and product quality. They create detailed CAD models, perform simulations, and collaborate with cross-functional teams to ensure tooling meets engineering specifications and manufacturing requirements. Their role requires expertise in materials, machining processes, and cost-effective design solutions to support seamless production workflows.

Overview of Tooling Design Engineer Role

| Overview of Tooling Design Engineer Role | |

|---|---|

| Job Title | Tooling Design Engineer |

| Primary Focus | Design and development of manufacturing tools and equipment |

| Key Responsibilities |

|

| Required Skills |

|

| Educational Background | Bachelor's degree in Mechanical Engineering, Manufacturing Engineering, or related field |

| Industry Applications | Automotive, aerospace, consumer electronics, heavy machinery, medical devices |

| Objective | Develop efficient, cost-effective tooling solutions that improve product quality and manufacturing productivity |

Key Responsibilities of a Tooling Design Engineer

A Tooling Design Engineer develops and optimizes tools used in manufacturing processes to ensure precision and efficiency. They collaborate closely with production and quality teams to design tools that meet specific product requirements.

This role involves creating detailed technical drawings, selecting appropriate materials, and utilizing CAD software for tool design. The engineer also conducts testing and validation to ensure tool functionality and durability during production.

Essential Skills for Tooling Design Engineers

Tooling Design Engineers require a strong understanding of CAD software, manufacturing processes, and materials science to create efficient and precise tooling solutions. Proficiency in problem-solving, attention to detail, and knowledge of mechanical systems ensures the design of reliable and cost-effective tools. Your ability to collaborate with cross-functional teams and interpret technical specifications is essential for successful project execution.

Educational Requirements and Qualifications

Tooling Design Engineers require a strong educational foundation in engineering principles, particularly mechanical or manufacturing engineering. Relevant qualifications and certifications enhance their capability to design efficient and precise tooling systems.

- Bachelor's Degree in Engineering - A degree in mechanical, manufacturing, or industrial engineering is typically required to understand tooling design fundamentals.

- Proficiency in CAD Software - Expertise in computer-aided design (CAD) tools such as SolidWorks or AutoCAD is essential for creating detailed tooling layouts.

- Industry Certifications - Certifications like Certified Manufacturing Engineer (CMfgE) or Six Sigma can validate skills in process optimization and quality control.

Continuous learning and practical experience remain critical for success in tooling design engineering careers.

Tools and Software Commonly Used

What tools and software do Tooling Design Engineers commonly use to enhance precision? Tooling Design Engineers frequently utilize CAD software like AutoCAD and SolidWorks to create detailed designs with high accuracy. Simulation tools such as ANSYS help test and optimize tooling performance before manufacturing.

How does software integration benefit tooling design processes? Integrating CAM software like Mastercam allows seamless transition from design to manufacturing, improving efficiency and reducing errors. Software such as Siemens NX provides comprehensive toolpath planning and analysis, enhancing production quality.

Which software supports collaboration among tooling design teams? Platforms like Autodesk Fusion 360 enable real-time collaboration and version control, ensuring your team stays aligned throughout the project lifecycle. Cloud-based solutions improve accessibility and streamline communication between engineers and stakeholders.

Importance of Tooling Design in Manufacturing

Tooling design engineering plays a crucial role in manufacturing by ensuring precision and efficiency in production processes. Proper tooling design enhances product quality, reduces waste, and minimizes production time, directly impacting overall manufacturing costs. Advanced CAD software and materials science are integral to creating durable, high-performance tools tailored for specific manufacturing needs.

Collaboration with Cross-Functional Teams

Tooling Design Engineers play a crucial role in product development by collaborating closely with cross-functional teams. Their expertise ensures efficient design and manufacturing processes.

These engineers work alongside product designers, manufacturing specialists, and quality assurance teams to optimize tooling solutions. Effective communication across departments reduces errors and accelerates project timelines. This collaboration drives innovation and maintains high standards in production quality.

Challenges Faced by Tooling Design Engineers

Tooling Design Engineers encounter complex challenges that demand precision and innovation to optimize manufacturing processes. Overcoming these difficulties is critical to ensure quality, efficiency, and cost-effectiveness in production.

- Material Selection Constraints - Choosing appropriate materials that balance durability, cost, and machinability requires in-depth knowledge and testing.

- Tight Tolerances and Accuracy - Designing tools that meet stringent dimensional tolerances necessitates advanced CAD modeling and simulation techniques.

- Integration with Manufacturing Systems - Ensuring tooling designs are compatible with existing machinery and production workflows demands comprehensive system understanding.

Career Path and Advancement Opportunities

Tooling Design Engineers develop specialized tools and equipment to improve manufacturing processes. Their expertise drives innovation and efficiency in production environments.

- Entry-Level Positions - Typically start as junior designers supporting tooling projects and learning CAD software.

- Mid-Level Roles - Involve managing tooling design projects, collaborating with cross-functional teams, and optimizing tool functionality.

- Senior and Leadership Opportunities - Include leading engineering teams, overseeing large-scale tooling programs, and influencing strategic manufacturing decisions.

Future Trends in Tooling Design Engineering

Tooling Design Engineers are increasingly integrating advanced technologies such as AI and machine learning to enhance precision and efficiency in manufacturing processes. These innovations enable predictive maintenance and optimize tool performance, reducing downtime and costs.

Future trends highlight the adoption of additive manufacturing for creating complex tooling geometries that were previously impossible with traditional methods. Emphasis on sustainable materials and energy-efficient designs is also driving the evolution of tooling systems in engineering industries.

Related Important Terms

Additive Tooling Fixtures

Tooling Design Engineers specializing in additive tooling fixtures leverage advanced 3D printing technologies to create precise, lightweight, and customizable components that enhance manufacturing efficiency. Their expertise in designing adaptable fixtures reduces lead times and material waste, advancing production scalability and quality control in complex engineering applications.

Digital Twin Simulation

Tooling Design Engineers leverage Digital Twin Simulation to create virtual replicas of manufacturing tools, enabling precise analysis and optimization of design, function, and performance before physical production. This integration reduces development time, minimizes errors, and enhances tool lifecycle management through predictive maintenance and real-time data monitoring.

Generative Design Optimization

Tooling Design Engineers leveraging Generative Design Optimization utilize advanced algorithms and AI-driven software to create efficient, lightweight, and cost-effective tooling solutions. This approach significantly enhances manufacturing precision, reduces material waste, and accelerates product development cycles in industrial engineering applications.

Topology-Optimized Tooling

Topology-optimized tooling design leverages advanced computational algorithms to create lightweight, high-strength tools with improved material efficiency and performance. This approach significantly reduces manufacturing costs and cycle times while enhancing tool durability and precision in engineering applications.

Hybrid Manufacturing Toolpaths

A Tooling Design Engineer specializing in Hybrid Manufacturing Toolpaths integrates additive and subtractive processes to optimize precision and material utilization in complex tool geometries. Leveraging advanced CAD/CAM software, they develop customized machining strategies that enhance cycle times and reduce tooling costs in aerospace and automotive production.

Tooling Design Engineer Infographic

jobdayta.com

jobdayta.com