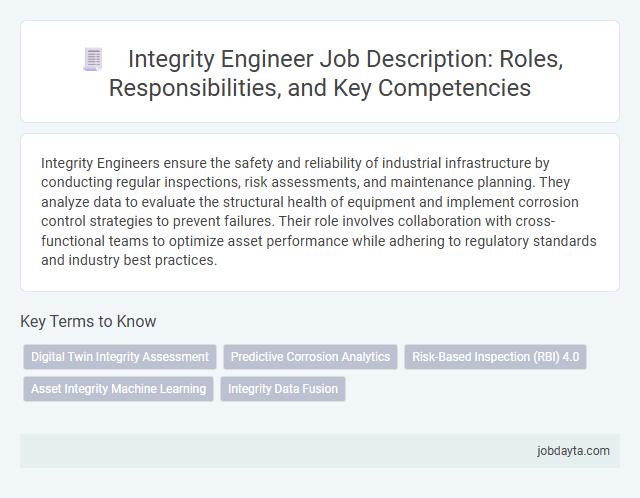

Integrity Engineers ensure the safety and reliability of industrial infrastructure by conducting regular inspections, risk assessments, and maintenance planning. They analyze data to evaluate the structural health of equipment and implement corrosion control strategies to prevent failures. Their role involves collaboration with cross-functional teams to optimize asset performance while adhering to regulatory standards and industry best practices.

Overview of Integrity Engineering in Industry

What is the role of an Integrity Engineer in the industry?

Integrity Engineers ensure the safety and reliability of equipment and structures through rigorous inspection and analysis. They apply engineering principles to prevent failures and extend the service life of assets in sectors such as oil and gas, manufacturing, and energy.

Core Roles and Responsibilities of an Integrity Engineer

An Integrity Engineer ensures the structural reliability and safety of assets by assessing potential risks and implementing preventative measures. You analyze inspection data, monitor material degradation, and develop maintenance strategies that comply with industry standards. Core responsibilities include conducting failure analyses, managing integrity management programs, and collaborating with multidisciplinary teams to optimize asset performance.

Essential Skills and Competencies for Integrity Engineers

Integrity Engineers play a vital role in ensuring the safety, reliability, and longevity of industrial assets. Their expertise is critical in risk assessment and maintaining compliance with engineering standards.

- Technical Knowledge - Proficient understanding of materials science, corrosion mechanisms, and structural analysis to evaluate asset integrity accurately.

- Risk Assessment Skills - Ability to identify and quantify potential hazards, using tools such as FMEA and RBI to prioritize maintenance activities.

- Regulatory Compliance - Familiarity with industry standards like API, ASME, and ISO to ensure all engineering practices meet legal and safety requirements.

Integrity Assessment and Risk Management Techniques

Integrity Engineers play a crucial role in maintaining the safety and reliability of engineering systems through detailed integrity assessment. Risk management techniques are essential tools they use to identify, evaluate, and mitigate potential failures in infrastructure.

- Integrity Assessment - Systematic evaluation of equipment condition to prevent unexpected failures and extend asset life.

- Risk Management Techniques - Application of methods like FMEA and HAZOP to anticipate hazards and reduce operational risks.

- Regulatory Compliance - Ensuring that engineering practices adhere to industry standards and legal requirements for safety and performance.

Inspection and Maintenance Planning in Integrity Engineering

Integrity Engineers specialize in ensuring the reliability and safety of assets through rigorous inspection and maintenance planning. Their expertise minimizes risks and extends the operational lifespan of critical infrastructure by systematically evaluating material degradation and structural integrity. You benefit from optimized maintenance schedules that enhance asset performance while reducing unexpected failures and downtime.

Materials and Corrosion Management Strategies

An Integrity Engineer specializing in Materials and Corrosion Management Strategies plays a critical role in ensuring the durability and safety of industrial assets. Their expertise focuses on selecting appropriate materials and implementing preventive measures to mitigate corrosion-related failures.

This engineer conducts thorough assessments of material properties and environmental factors to develop effective corrosion control plans. They utilize advanced techniques such as corrosion monitoring, inspection protocols, and protective coatings to extend the lifespan of infrastructure. These strategies minimize maintenance costs while maximizing operational efficiency and safety in sectors like oil and gas, petrochemical, and power generation.

Regulatory Compliance and Safety Standards for Integrity Engineers

Integrity Engineers play a critical role in ensuring that engineering projects comply with regulatory frameworks and maintain high safety standards. Their expertise safeguards structural reliability and operational security across industries.

- Regulatory Compliance Management - Integrity Engineers ensure all design, construction, and maintenance activities meet local, national, and international regulations.

- Safety Standards Implementation - They develop and enforce safety protocols to prevent accidents and mitigate risks throughout a structure's lifecycle.

- Risk Assessment and Mitigation - Integrity Engineers perform detailed analyses to identify potential failures and implement corrective actions proactively.

Adhering to regulatory compliance and rigorous safety standards is essential for Integrity Engineers to protect both assets and human lives.

Use of Technology and Software in Integrity Engineering

Integrity engineers utilize advanced technology and software to monitor the health and safety of critical infrastructure. These tools enable precise data analysis and predictive maintenance, reducing the risk of failures.

Software such as finite element analysis (FEA) and corrosion monitoring systems play a vital role in integrity assessments. Automation and real-time data collection through sensors enhance decision-making and operational efficiency.

Career Path and Professional Development for Integrity Engineers

| Aspect | Details |

|---|---|

| Role Overview | An Integrity Engineer ensures the structural integrity, safety, and reliability of engineering systems and infrastructure throughout their lifecycle. |

| Core Responsibilities | Risk assessment, failure analysis, inspection planning, maintenance strategy development, corrosion management, and compliance monitoring. |

| Required Education | Bachelor's degree in Mechanical, Civil, Structural, or Offshore Engineering. Advanced degrees or certifications preferred. |

| Key Certifications | API 570 (Piping Inspector), API 653 (Tank Inspector), NACE Corrosion Technician, Certified Integrity Engineer (CIE). |

| Essential Skills | Materials science knowledge, fitness-for-service evaluation, risk-based inspection (RBI), data analysis, software proficiency (e.g., corrosion modeling tools, FEA software). |

| Career Path Progression | Junior Integrity Engineer - Integrity Engineer - Senior Integrity Engineer - Integrity Manager - Asset Integrity Lead - Technical Director. |

| Professional Development | Continuous technical training, participation in industry workshops, conferences such as NACE CORROSION, networking through professional societies like ASME and Energy Institute. |

| Industry Sectors | Oil & Gas, Petrochemical, Power Generation, Maritime, Manufacturing, Water Treatment. |

| Emerging Trends | Integration of digital inspection techniques, use of AI for predictive maintenance, advanced corrosion monitoring, sustainability-focused integrity management. |

| Impact | Ensures asset longevity, minimizes failure risk, enhances safety standards, reduces maintenance costs, and supports regulatory compliance. |

Challenges and Future Trends in Integrity Engineering

Integrity engineers play a crucial role in ensuring the safety and reliability of industrial assets through rigorous inspection, assessment, and maintenance strategies. Their work addresses complex challenges such as material degradation, corrosion, and structural fatigue that threaten asset longevity.

Emerging technologies like digital twins, AI-driven predictive analytics, and advanced nondestructive testing are transforming integrity engineering practices. Future trends emphasize real-time monitoring and data integration to enhance proactive asset management and reduce operational risks.

Related Important Terms

Digital Twin Integrity Assessment

Integrity Engineers specializing in Digital Twin Integrity Assessment utilize advanced simulation models to monitor and predict the structural health of engineering assets in real time, enhancing safety and operational efficiency. Digital twins enable precise diagnostics by integrating sensor data with predictive analytics, facilitating proactive maintenance and extending asset lifespan.

Predictive Corrosion Analytics

Integrity engineers specializing in predictive corrosion analytics leverage advanced data modeling and sensor technologies to forecast corrosion rates and prevent structural failures in industrial assets. Their expertise in materials science, nondestructive testing, and real-time monitoring enables optimized maintenance strategies and extends the operational lifespan of critical infrastructure.

Risk-Based Inspection (RBI) 4.0

Integrity Engineers specializing in Risk-Based Inspection (RBI) 4.0 leverage advanced data analytics and machine learning algorithms to enhance predictive maintenance and optimize inspection schedules, significantly reducing equipment failure risks. Implementing RBI 4.0 integrates real-time sensor data, historical inspection records, and corrosion modeling to prioritize high-risk assets and improve operational safety and cost efficiency in engineering systems.

Asset Integrity Machine Learning

Integrity engineers utilize advanced machine learning algorithms to monitor and predict the condition of critical assets, enhancing safety and operational reliability. By analyzing sensor data and historical maintenance records, these specialists optimize inspection schedules and prevent unexpected equipment failures in industrial environments.

Integrity Data Fusion

Integrity engineers specializing in integrity data fusion utilize advanced algorithms and real-time sensor data to monitor structural health and predict failure points in critical infrastructure. Their expertise enhances asset reliability by integrating diverse data sources into comprehensive integrity assessments, minimizing maintenance costs and preventing catastrophic failures.

Integrity Engineer Infographic

jobdayta.com

jobdayta.com