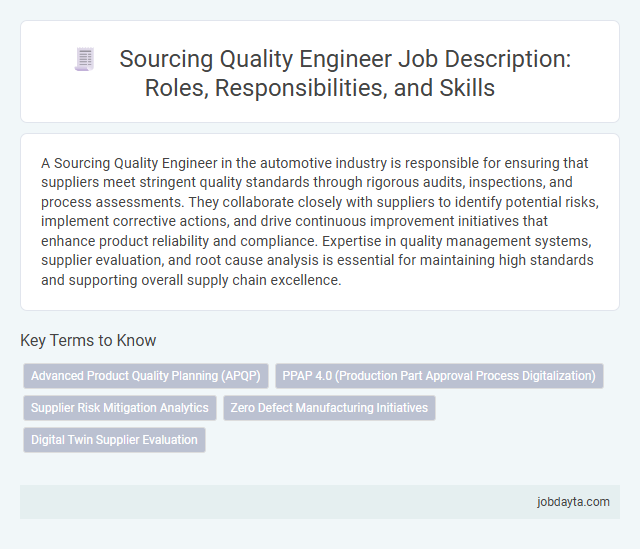

A Sourcing Quality Engineer in the automotive industry is responsible for ensuring that suppliers meet stringent quality standards through rigorous audits, inspections, and process assessments. They collaborate closely with suppliers to identify potential risks, implement corrective actions, and drive continuous improvement initiatives that enhance product reliability and compliance. Expertise in quality management systems, supplier evaluation, and root cause analysis is essential for maintaining high standards and supporting overall supply chain excellence.

Overview of a Sourcing Quality Engineer in Automotive

A Sourcing Quality Engineer in the automotive industry ensures that purchased components meet rigorous quality standards and specifications. They collaborate with suppliers to implement quality control processes, conduct audits, and resolve non-conformances to maintain product reliability. Their role is critical in minimizing defects, reducing costs, and supporting continuous improvement across the supply chain.

Key Roles and Responsibilities

The Sourcing Quality Engineer ensures that all automotive suppliers meet strict quality standards through rigorous evaluation and continuous monitoring of production processes. You collaborate closely with cross-functional teams to identify quality improvement opportunities and resolve supplier-related issues promptly. This role involves conducting audits, analyzing defect data, and implementing corrective actions to maintain compliance with industry regulations and internal quality benchmarks.

Essential Technical Skills for Sourcing Quality Engineers

Sourcing Quality Engineers in the automotive industry must possess a deep understanding of quality management systems such as IATF 16949 and ISO 9001. Proficiency in Failure Mode and Effects Analysis (FMEA) and Advanced Product Quality Planning (APQP) is critical for identifying potential risks and ensuring supplier quality compliance.

Expertise in Root Cause Analysis (RCA) and Corrective and Preventive Actions (CAPA) enables engineers to resolve supplier-related quality issues effectively. Strong skills in data analysis tools like Minitab and statistical process control (SPC) support continuous improvement and performance monitoring of sourced components.

Importance of Quality Assurance in Automotive Sourcing

The role of a Sourcing Quality Engineer is critical in the automotive industry to ensure that all sourced components meet rigorous quality standards. High-quality sourcing directly impacts vehicle safety, performance, and customer satisfaction.

Quality assurance in automotive sourcing minimizes risks associated with defective parts, reducing recalls and warranty costs. Effective quality control processes ensure supplier compliance with industry standards such as IATF 16949. Your attention to detail as a Sourcing Quality Engineer helps maintain the integrity and reliability of the entire supply chain.

Collaboration with Suppliers and Manufacturing Teams

Sourcing Quality Engineers play a crucial role in the automotive industry by ensuring supplier components meet rigorous quality standards. They work closely with suppliers to identify potential issues and implement corrective actions early in the production cycle.

Collaboration with manufacturing teams is essential to align quality requirements with production capabilities. These engineers facilitate continuous communication between suppliers and manufacturing to optimize process efficiency and product reliability.

Tools and Software Commonly Used in Sourcing Quality Engineering

Sourcing Quality Engineers in the automotive industry utilize specialized tools and software to ensure supplier compliance and product quality. Mastery of these digital resources enhances efficiency in quality inspections and data analysis.

- Statistical Process Control (SPC) Software - Enables monitoring and controlling manufacturing processes to maintain product quality through statistical methods.

- Supplier Quality Management (SQM) Systems - Facilitates tracking and auditing supplier performance, ensuring adherence to automotive industry standards.

- Computer-Aided Design (CAD) Tools - Used for reviewing and validating supplier product designs to meet technical specifications and reduce defects.

Challenges Faced by Sourcing Quality Engineers in Automotive

Sourcing Quality Engineers in the automotive industry encounter complex challenges that impact product reliability and supplier performance. Managing these difficulties requires a keen understanding of quality standards and supply chain dynamics.

- Supplier Compliance Management - Ensuring all suppliers adhere to strict automotive quality standards and regulations can be difficult and time-consuming.

- Defect Tracking and Resolution - Identifying, documenting, and resolving quality defects across multiple vendors demands effective communication and swift action.

- Integration of New Technologies - Adapting to emerging automotive manufacturing technologies while maintaining quality benchmarks presents continuous hurdles.

Your role is critical in overcoming these challenges to maintain safety, efficiency, and customer satisfaction.

Qualifications and Educational Requirements

| Qualification | Bachelor's degree in Mechanical Engineering, Industrial Engineering, or a related field. Proven experience in automotive quality assurance or sourcing processes. Strong understanding of ISO/TS 16949 and automotive industry standards. Proficiency in root cause analysis, statistical methods, and quality tools such as FMEA and PPAP. Excellent communication skills to liaise effectively with suppliers and cross-functional teams. |

|---|---|

| Educational Requirements | A minimum of a bachelor's degree in Engineering or a relevant technical discipline is essential. Advanced certifications like Six Sigma Green Belt or APICS CPIM enhance your credentials. Coursework or formal training in supply chain management, quality control, and automotive manufacturing technologies is highly preferred. |

Career Path and Advancement Opportunities

What career path can a Sourcing Quality Engineer expect in the automotive industry? A Sourcing Quality Engineer typically begins with supplier quality audits and product validation. Progression often leads to roles such as Senior Quality Engineer, Supplier Development Manager, or Quality Assurance Director.

How do advancement opportunities manifest in this role? Technical expertise and strong supplier management skills open pathways to leadership positions. Growth also includes specialization in areas like risk management or supply chain optimization.

What skills are key to advancing as a Sourcing Quality Engineer in automotive? Proficiency in quality standards such as IATF 16949 and strong analytical abilities are essential. Networking within cross-functional teams enhances your visibility and career mobility.

How does the automotive industry's evolution impact your career growth? Advancements in electric vehicles and autonomous driving technology create new sourcing quality challenges. Staying updated with industry trends boosts potential for career progression.

Impact of Sourcing Quality Engineers on Automotive Product Reliability

Sourcing Quality Engineers play a critical role in ensuring the reliability of automotive products by overseeing supplier quality standards. Their expertise directly impacts the performance, safety, and durability of vehicles throughout their lifecycle.

Improving supplier quality controls reduces defect rates and enhances component consistency. Identifying potential quality risks early prevents costly recalls and warranty claims. Collaboration with suppliers fosters innovation and continuous improvement in automotive manufacturing.

- Risk Mitigation - Sourcing Quality Engineers implement strict quality audits that minimize the risk of defective parts entering the supply chain.

- Supplier Collaboration - They work closely with suppliers to establish quality benchmarks driving the production of high-reliability components.

- Product Longevity - Their involvement ensures that sourced materials and parts contribute to the extended durability and safety of the final automotive product.

Related Important Terms

Advanced Product Quality Planning (APQP)

A Sourcing Quality Engineer specializing in Advanced Product Quality Planning (APQP) drives supplier quality improvement through rigorous process audits, failure mode effects analysis (FMEA), and control plan development, ensuring compliance with automotive industry standards like IATF 16949. They collaborate with cross-functional teams to establish robust quality controls early in the supply chain, reducing defects and enabling timely production launches for automotive components.

PPAP 4.0 (Production Part Approval Process Digitalization)

Sourcing Quality Engineers leverage PPAP 4.0 to enhance digital traceability and streamline supplier part approval workflows, ensuring compliance with automotive industry standards such as IATF 16949. This digital transformation of the Production Part Approval Process enables real-time data integration, accelerating issue detection and reducing part non-conformances across global supply chains.

Supplier Risk Mitigation Analytics

Sourcing Quality Engineers utilize advanced supplier risk mitigation analytics to identify and address potential supply chain vulnerabilities in the automotive sector, ensuring component reliability and compliance with industry standards such as IATF 16949. By integrating real-time data analytics and predictive modeling, they proactively manage supplier performance risks, reducing defects and production delays while enhancing overall procurement quality.

Zero Defect Manufacturing Initiatives

Sourcing Quality Engineers drive Zero Defect Manufacturing Initiatives by implementing rigorous supplier quality audits, real-time defect analysis, and corrective action protocols to ensure automotive component reliability. Their expertise in quality data analytics and root cause failure investigations optimizes supply chain processes, reducing defects and enhancing production efficiency.

Digital Twin Supplier Evaluation

A Sourcing Quality Engineer specializing in Digital Twin Supplier Evaluation leverages virtual replicas to assess supplier performance, ensuring compliance with automotive industry standards and reducing physical prototyping costs. This approach enhances real-time quality monitoring, accelerates supplier audits, and drives continuous improvement in component reliability and manufacturing efficiency.

Sourcing Quality Engineer Infographic

jobdayta.com

jobdayta.com