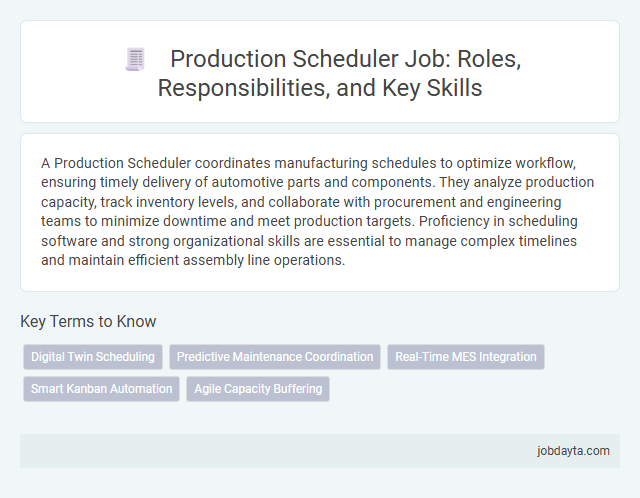

A Production Scheduler coordinates manufacturing schedules to optimize workflow, ensuring timely delivery of automotive parts and components. They analyze production capacity, track inventory levels, and collaborate with procurement and engineering teams to minimize downtime and meet production targets. Proficiency in scheduling software and strong organizational skills are essential to manage complex timelines and maintain efficient assembly line operations.

Introduction to Production Scheduler Role in Automotive

| Role | Production Scheduler |

|---|---|

| Industry | Automotive Manufacturing |

| Primary Responsibility | Coordinating and optimizing production schedules to ensure timely assembly and delivery of automotive components and vehicles. |

| Key Functions | Planning production runs, managing inventory levels, tracking order progress, and adjusting schedules based on supply chain dynamics and demand fluctuations. |

| Importance | Crucial for minimizing downtime, maximizing manufacturing efficiency, and meeting customer demands in a competitive automotive market. |

| Skills Required | Strong analytical abilities, knowledge of manufacturing processes, proficiency in scheduling software, and communication skills for coordinating between departments. |

| Your Role | As a Production Scheduler, you ensure smooth workflow in automotive production lines by creating effective schedules that balance resources, capacity, and deadlines. |

Key Responsibilities of an Automotive Production Scheduler

The Automotive Production Scheduler coordinates production schedules to ensure timely delivery of vehicles and components. You manage inventory levels, align manufacturing capacity with demand forecasts, and resolve scheduling conflicts to maintain efficient workflows. Monitoring production progress and communicating with supply chain teams are essential responsibilities to minimize downtime and meet quality standards.

Essential Skills for Effective Production Scheduling

Effective production scheduling in the automotive industry requires strong organizational skills and attention to detail. Mastery of software tools and real-time data analysis ensures that production timelines stay on track.

Clear communication abilities facilitate coordination between departments, preventing delays and optimizing workflow. You must also demonstrate problem-solving skills to quickly address unexpected disruptions in the production line.

How Production Schedulers Optimize Automotive Manufacturing

Production schedulers play a critical role in optimizing automotive manufacturing by coordinating workflows and ensuring materials are available at the right time. They analyze production data and adjust schedules to minimize downtime and balance workloads across assembly lines. By implementing efficient scheduling strategies, you can improve productivity, reduce costs, and accelerate vehicle delivery timelines.

Tools and Software Used by Automotive Production Schedulers

Automotive production schedulers rely on advanced tools and software to optimize manufacturing workflows and ensure timely vehicle assembly. These technologies enable precise coordination of materials, labor, and machine utilization in a fast-paced automotive environment.

- Enterprise Resource Planning (ERP) Systems - Integrate core automotive production processes, from inventory management to supply chain coordination, enhancing overall efficiency.

- Advanced Planning and Scheduling (APS) Software - Provides detailed scheduling capabilities that adapt to production constraints and dynamic changes in automotive manufacturing.

- Manufacturing Execution Systems (MES) - Track real-time production data on the shop floor to monitor progress, quality, and equipment performance in automotive plants.

Effective use of these tools ensures on-time vehicle production, reduces downtime, and improves resource allocation in automotive manufacturing.

Challenges Faced by Production Schedulers in the Automotive Industry

Production schedulers in the automotive industry manage complex processes to ensure timely vehicle assembly. They face numerous challenges that impact manufacturing efficiency and delivery deadlines.

- Supply Chain Disruptions - Delays in parts delivery from suppliers disrupt production timelines and increase downtime.

- Demand Variability - Fluctuating customer orders require frequent adjustments to schedules, complicating resource allocation.

- Integration of Technology - Implementing and synchronizing advanced manufacturing systems demands continuous training and adaptation.

Impact of Production Scheduling on Automotive Supply Chain Efficiency

Production scheduling is a critical component in the automotive industry, directly affecting the efficiency of the supply chain. It determines the timing and quantity of parts and vehicles produced, optimizing resource use and reducing delays.

An effective production scheduler aligns manufacturing processes with supplier deliveries and customer demand, minimizing inventory costs and avoiding production bottlenecks. Improved scheduling enhances communication across the supply chain, leading to better coordination and faster response times. Your ability to implement precise scheduling strategies can significantly boost overall supply chain performance and vehicle delivery timelines.

Career Path and Growth Opportunities for Production Schedulers

What career path options are available for a Production Scheduler in the automotive industry? Production Schedulers often start as coordinators or planners and advance to senior scheduling roles or production management positions. Many progress into supply chain management or operations leadership, leveraging their expertise in workflow optimization and resource allocation.

How can a Production Scheduler achieve growth within an automotive manufacturing company? Gaining proficiency in ERP systems, lean manufacturing, and advanced scheduling software enhances promotion prospects. Continuous learning and certifications in project management or supply chain analytics often lead to expanded responsibilities and leadership roles.

Best Practices for Successful Production Scheduling in Automotive Plants

Efficient production scheduling is critical to maintaining smooth operations in automotive plants. Implementing best practices helps optimize workflow, reduce downtime, and meet delivery deadlines.

- Leverage Real-Time Data Integration - Utilizing live data from machines and supply chains enables dynamic adjustments to the production schedule, enhancing responsiveness and reducing bottlenecks.

- Apply Advanced Scheduling Software - Employing specialized tools designed for automotive manufacturing improves accuracy in forecasting demand and allocating resources.

- Foster Cross-Departmental Collaboration - Encouraging communication between production, procurement, and quality control teams ensures alignment and prevents schedule disruptions.

Future Trends Shaping the Role of Automotive Production Schedulers

The future of automotive production scheduling is increasingly influenced by advancements in AI and machine learning algorithms. These technologies enable more accurate forecasting and dynamic adjustment to production plans.

Digital twins and real-time data analytics will transform how you optimize manufacturing workflows. Embracing these innovations ensures higher efficiency and reduced downtime in automotive production lines.

Related Important Terms

Digital Twin Scheduling

Digital Twin Scheduling in automotive production leverages real-time data simulations to optimize manufacturing workflows, reduce downtime, and enhance resource allocation. Integrating digital twin technology enables production schedulers to predict bottlenecks and dynamically adjust schedules, increasing overall efficiency and throughput.

Predictive Maintenance Coordination

Production schedulers in automotive manufacturing leverage predictive maintenance coordination to optimize equipment uptime and reduce unplanned downtime by analyzing real-time sensor data and machine learning algorithms. This approach enables proactive scheduling adjustments that align maintenance activities with production demands, enhancing overall assembly line efficiency.

Real-Time MES Integration

A Production Scheduler integrated with Real-Time MES (Manufacturing Execution System) enhances automotive manufacturing efficiency by synchronizing production workflows and machine data instantaneously. This integration enables dynamic adjustment of schedules based on live shop floor conditions, reducing downtime and optimizing resource allocation for just-in-time vehicle assembly.

Smart Kanban Automation

Smart Kanban Automation in automotive production scheduling streamlines inventory management by using real-time data to trigger precise material replenishment, reducing waste and minimizing downtime. This technology enhances manufacturing efficiency through seamless integration with ERP systems, ensuring just-in-time delivery aligned with production demands.

Agile Capacity Buffering

Agile capacity buffering in automotive production scheduling enables dynamic adjustment of manufacturing outputs to absorb fluctuations in demand and supply chain disruptions, enhancing overall operational resilience. Implementing real-time data analytics and predictive modeling allows schedulers to optimize resource allocation, minimize downtime, and maintain efficient workflow continuity across assembly lines.

Production Scheduler Infographic

jobdayta.com

jobdayta.com