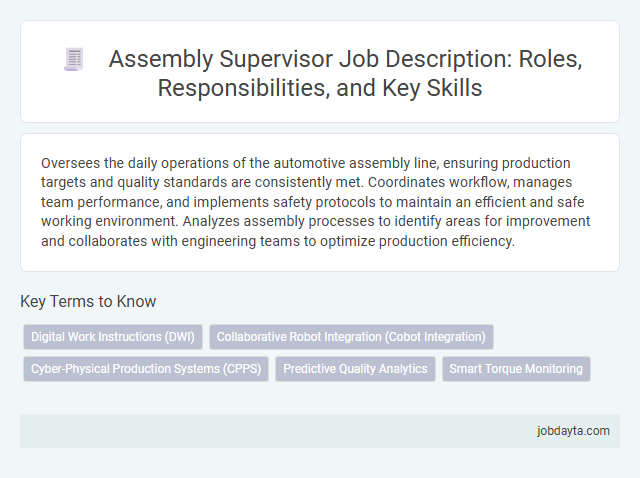

Oversees the daily operations of the automotive assembly line, ensuring production targets and quality standards are consistently met. Coordinates workflow, manages team performance, and implements safety protocols to maintain an efficient and safe working environment. Analyzes assembly processes to identify areas for improvement and collaborates with engineering teams to optimize production efficiency.

Overview of Assembly Supervisor Role in Automotive Industry

The Assembly Supervisor in the automotive industry plays a critical role in overseeing the production line to ensure efficient vehicle assembly. This position requires comprehensive knowledge of assembly processes, quality control, and safety standards.

You are responsible for managing a team of assemblers, coordinating workflow, and maintaining adherence to production schedules. Effective communication with engineering and quality departments is essential to address issues promptly. Ensuring compliance with industry regulations and optimizing assembly efficiency drives overall manufacturing success.

Key Responsibilities of an Assembly Supervisor

| Key Responsibilities of an Assembly Supervisor in Automotive | |

|---|---|

| Production Management | Oversee all stages of vehicle assembly ensuring adherence to production schedules and quality standards. |

| Team Leadership | Supervise and coordinate assembly line workers, providing guidance and training to optimize efficiency and safety. |

| Quality Control | Implement quality assurance protocols, monitor inspection processes, and address defects promptly to maintain product excellence. |

| Safety Compliance | Enforce workplace safety regulations and promote a culture of safety to minimize accidents and comply with industry standards. |

| Performance Monitoring | Track key performance indicators (KPIs) such as production output, cycle time, and downtime to drive continuous improvement. |

| Resource Allocation | Manage materials and equipment availability, ensuring smooth workflow and reducing bottlenecks on the assembly line. |

| Problem Solving | Identify issues in assembly processes and implement corrective actions swiftly to maintain operational efficiency. |

| Communication | Act as the liaison between production staff and upper management, reporting progress, challenges, and improvements. |

| Continuous Improvement | Promote Lean manufacturing principles and encourage innovation to enhance assembly line productivity. |

| Your Role | Drive team performance by fostering a collaborative environment focused on meeting and exceeding automotive assembly goals. |

Essential Skills Required for Assembly Supervisors

Assembly Supervisors play a critical role in automotive manufacturing, ensuring production processes meet quality and efficiency standards. Mastery of essential skills is necessary to lead teams and optimize assembly line performance.

- Leadership Ability - Drive team motivation and manage workforce dynamics to maintain consistent assembly line productivity.

- Technical Knowledge - Understand automotive components, tools, and assembly techniques to oversee accurate and effective production.

- Problem-Solving Skills - Quickly identify and resolve issues that arise on the assembly line to minimize downtime and defects.

Your expertise in these areas directly impacts the success of automotive assembly operations and overall vehicle quality.

Daily Tasks and Workflow Management

What are the primary daily tasks of an Assembly Supervisor in the automotive industry? Monitoring assembly line operations ensures product quality and adherence to production schedules. Coordinating team activities and resolving workflow issues maintain efficient assembly processes.

How does an Assembly Supervisor manage workflow effectively? Organizing task assignments and tracking progress minimize downtime and optimize resource use. Implementing quality control checks keeps the production standards consistent throughout the shift.

What role does communication play in your workflow management? Clear instructions and timely feedback promote team collaboration and problem-solving. Reporting production metrics to management supports continuous improvement efforts in automotive assembly.

Leadership and Team Management in Assembly Lines

The Assembly Supervisor plays a critical role in overseeing production lines within the automotive manufacturing process, ensuring smooth operations and quality output. Strong leadership skills are essential for managing diverse teams, coordinating workflow, and maintaining safety standards. Effective communication and team management foster collaboration, driving efficiency and meeting assembly targets on time.

Quality Control and Compliance Duties

The Assembly Supervisor plays a critical role in overseeing quality control measures to ensure all automotive components meet strict industry standards. This position involves rigorous inspection processes and adherence to compliance protocols to maintain production integrity and safety regulations. Your responsibility includes coordinating with teams to implement corrective actions swiftly when deviations from quality benchmarks occur.

Safety Standards and Protocols Enforcement

As an Assembly Supervisor in the automotive industry, enforcing safety standards and protocols is crucial to maintaining a secure work environment. Strict adherence to OSHA regulations and internal safety guidelines minimizes risks and prevents workplace accidents.

Your role includes conducting regular safety audits and training sessions to ensure all assembly line workers understand and follow proper procedures. Proactive identification and mitigation of hazards protect both employees and production efficiency.

Communication and Coordination with Cross-Functional Teams

Effective communication and coordination with cross-functional teams are essential for the Assembly Supervisor to ensure seamless production flow. Your ability to connect departments fosters collaboration and resolves issues quickly, impacting overall vehicle assembly quality.

- Facilitating Clear Communication - Regularly conveying assembly progress and challenges to engineering, quality control, and supply chain teams ensures alignment on project goals.

- Coordinating Multi-Department Tasks - Synchronizing schedules and resources across design, manufacturing, and maintenance teams prevents delays and optimizes workflow.

- Resolving Cross-Functional Issues - Leading problem-solving sessions with diverse teams drives timely resolution of assembly roadblocks and improves productivity.

Training and Development of Assembly Line Workers

The Assembly Supervisor plays a critical role in enhancing the skills and efficiency of assembly line workers. Implementing structured training programs ensures consistent product quality and reduces assembly errors.

Ongoing development opportunities empower workers to adapt to new technologies and processes. Your leadership in training directly contributes to improved productivity and workplace safety.

Career Growth and Advancement Opportunities for Assembly Supervisors

Assembly Supervisors in the automotive industry play a crucial role in managing production lines and ensuring quality control. Career growth opportunities are abundant as companies invest in leadership development and technical training.

- Leadership Development Programs - Structured training enhances supervisory skills and prepares you for higher management roles.

- Technical Skill Advancement - Continuous learning in automotive technologies positions supervisors for specialized engineering or quality assurance roles.

- Cross-Departmental Opportunities - Exposure to logistics, supply chain, and manufacturing operations broadens career pathways beyond assembly supervision.

Related Important Terms

Digital Work Instructions (DWI)

Assembly Supervisors leverage Digital Work Instructions (DWI) to enhance precision and efficiency on automotive production lines, reducing errors by up to 30% and accelerating training processes for new operators by 40%. Real-time updates and interactive guidance streamline complex assembly tasks, ensuring consistent quality and compliance with industry standards such as ISO/TS 16949.

Collaborative Robot Integration (Cobot Integration)

Assembly Supervisors in automotive manufacturing drive efficiency and precision by overseeing Collaborative Robot Integration (Cobot Integration) to streamline production lines and enhance human-robot teamwork. Their expertise in programming and coordinating cobots ensures improved assembly accuracy, reduced downtime, and heightened workplace safety.

Cyber-Physical Production Systems (CPPS)

Assembly Supervisors in Automotive leveraging Cyber-Physical Production Systems (CPPS) drive real-time integration of machinery, robotics, and IoT sensors to optimize production efficiency and quality. Expertise in CPPS enables precise monitoring, adaptive control, and predictive maintenance, significantly reducing downtime and enhancing assembly line performance.

Predictive Quality Analytics

Assembly Supervisors leverage predictive quality analytics to monitor real-time production data, identifying potential defects before they occur and reducing rework rates by up to 30%. Implementing machine learning algorithms within automotive assembly lines enhances process stability and improves overall vehicle build quality metrics.

Smart Torque Monitoring

Smart Torque Monitoring enhances assembly efficiency by providing real-time data on tightening accuracy, reducing errors and component failures in automotive production lines. Assembly Supervisors leverage this technology to ensure precise torque application, improve quality control, and optimize workflow in manufacturing processes.

Assembly Supervisor Infographic

jobdayta.com

jobdayta.com