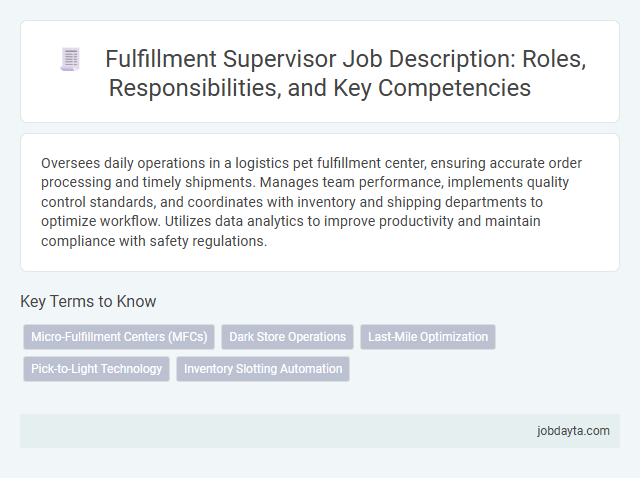

Oversees daily operations in a logistics pet fulfillment center, ensuring accurate order processing and timely shipments. Manages team performance, implements quality control standards, and coordinates with inventory and shipping departments to optimize workflow. Utilizes data analytics to improve productivity and maintain compliance with safety regulations.

Overview of a Fulfillment Supervisor Role in Logistics

A Fulfillment Supervisor in logistics oversees the timely and accurate processing of customer orders within a warehouse or distribution center. This role involves managing daily operations to ensure inventory control, order accuracy, and efficient workflow.

Your responsibilities include leading a team to meet performance targets while maintaining high safety and quality standards. Strong communication and organizational skills are essential to coordinate between various departments and optimize the fulfillment process.

Key Responsibilities of a Fulfillment Supervisor

The Fulfillment Supervisor oversees daily warehouse operations to ensure accurate order processing and timely shipment. They manage team performance, coordinate inventory control, and maintain compliance with safety regulations. Effective communication and problem-solving skills are essential to optimize workflow and meet customer delivery targets.

Essential Skills and Competencies for Fulfillment Supervisors

The role of a Fulfillment Supervisor is critical in ensuring smooth operations within logistics and supply chain management. Mastery of essential skills and competencies enables efficient order processing, team coordination, and timely delivery.

- Leadership Skills - Ability to motivate and manage a team effectively to meet productivity targets.

- Inventory Management - Expertise in tracking stock levels and controlling warehouse inventory to prevent shortages or surpluses.

- Communication Skills - Proficient in clear and concise communication to coordinate between departments and resolve issues promptly.

Daily Tasks and Workflow Management in Fulfillment Centers

The Fulfillment Supervisor oversees daily operations within fulfillment centers, ensuring timely and accurate order processing. They coordinate team activities to maintain efficient workflow and meet performance targets.

Key tasks include managing staff schedules, monitoring packing and shipping processes, and resolving operational issues promptly. The supervisor tracks inventory levels and ensures compliance with safety standards. Effective communication between departments supports seamless order fulfillment and customer satisfaction.

Leadership and Team Management in Fulfillment Operations

| Role | Fulfillment Supervisor |

|---|---|

| Focus | Leadership and Team Management in Fulfillment Operations |

| Leadership Responsibilities | Oversee daily fulfillment activities, coordinate workforce schedules, enforce safety and quality standards, and drive performance metrics to meet operational goals. |

| Team Management | Train, mentor, and motivate team members, resolve conflicts, foster a collaborative work environment, and ensure team adherence to fulfillment processes and timelines. |

| Operational Impact | Ensure smooth order processing, optimize pick-pack-ship workflows, reduce errors, and improve delivery accuracy to enhance customer satisfaction and supply chain efficiency. |

| Your Role | Empower your team by setting clear expectations and leading by example to drive consistent fulfillment success. |

Quality Control and Accuracy in Order Fulfillment

Ensuring quality control and accuracy in order fulfillment is critical to maintaining customer satisfaction in logistics operations. Effective oversight by a Fulfillment Supervisor guarantees that every order meets precise standards without errors.

- Quality Control Implementation - Enforces rigorous inspection procedures to verify product condition before shipment.

- Order Accuracy Monitoring - Utilizes advanced tracking systems to confirm each item matches order specifications exactly.

- Team Coordination - Oversees fulfillment staff to streamline processes and reduce errors during order preparation.

Inventory Management and Stock Control Duties

The Fulfillment Supervisor plays a critical role in overseeing inventory management and stock control to ensure efficient warehouse operations. This position requires meticulous attention to detail and strong organizational skills to maintain accurate inventory records and minimize stock discrepancies.

- Inventory Accuracy - Ensures all incoming and outgoing stock is accurately recorded to maintain precise inventory levels.

- Stock Replenishment - Monitors stock levels regularly and coordinates timely replenishment to avoid stockouts and overstock situations.

- Warehouse Coordination - Supervises warehouse staff in proper stock handling, storage, and cycle counting to optimize inventory turnover.

Effective inventory management and stock control by the Fulfillment Supervisor directly impact order fulfillment speed and customer satisfaction.

Ensuring Health and Safety Compliance in Fulfillment Areas

A Fulfillment Supervisor plays a critical role in maintaining health and safety compliance within fulfillment areas. This responsibility ensures that workplace standards meet regulatory requirements and protect all employees from potential hazards.

Regular safety audits and training sessions help identify risks and implement effective solutions. You oversee the adherence to safety protocols, promoting a secure environment for the entire logistics team.

Technology and Software Utilized by Fulfillment Supervisors

Fulfillment Supervisors leverage advanced warehouse management systems (WMS) such as Oracle Netsuite and Manhattan Associates to streamline order processing and inventory tracking. They utilize real-time data analytics tools to monitor performance metrics, ensuring efficient workflow and timely order fulfillment. Automation software, including robotic process automation (RPA) and barcode scanning technology, enhances accuracy and reduces manual errors in daily operations.

Career Path and Advancement Opportunities for Fulfillment Supervisors

What career paths are available for Fulfillment Supervisors in the logistics industry?

Fulfillment Supervisors can progress to roles such as Logistics Manager, Operations Manager, or Supply Chain Manager. Gaining experience in team leadership and process optimization enhances advancement opportunities.

How can Fulfillment Supervisors improve their chances of promotion within a logistics company?

Developing strong skills in inventory management, employee training, and operational efficiency is crucial. Pursuing certifications like APICS CPIM or Six Sigma boosts credibility and career growth.

What industries offer the most advancement opportunities for Fulfillment Supervisors?

E-commerce, retail, and third-party logistics (3PL) sectors highly value Fulfillment Supervisors. These industries provide dynamic environments with frequent openings for leadership roles.

Which qualifications support career advancement for a Fulfillment Supervisor?

A bachelor's degree in logistics, supply chain management, or business administration is beneficial. Professional development through workshops and management training accelerates promotion potential.

What leadership skills are essential for Fulfillment Supervisors seeking higher positions?

Effective communication, conflict resolution, and team motivation are critical leadership skills. Mastery of data-driven decision-making and process improvement leads to sustained career advancement.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

A Fulfillment Supervisor in Micro-Fulfillment Centers (MFCs) oversees order processing efficiency, ensuring rapid picking, packing, and shipping within compact automated environments. Expertise in inventory management software and robotics integration is essential to optimize throughput and reduce fulfillment turnaround times.

Dark Store Operations

A Fulfillment Supervisor in dark store operations manages inventory accuracy and order processing efficiency to optimize last-mile delivery speed and reduce operational costs. They coordinate picking and packing teams, implement quality control measures, and utilize warehouse management systems (WMS) to streamline fulfillment workflows.

Last-Mile Optimization

A Fulfillment Supervisor specializing in Last-Mile Optimization enhances delivery efficiency by coordinating route planning, reducing transit times, and managing carrier performance to ensure timely order completion. Leveraging analytics-driven insights and real-time tracking technologies enables proactive issue resolution and cost-effective fulfillment within urban logistics networks.

Pick-to-Light Technology

A Fulfillment Supervisor leveraging Pick-to-Light technology enhances order accuracy and reduces picking time by guiding workers through illuminated indicators corresponding to specific inventory locations. This system optimizes warehouse productivity and minimizes errors, ensuring efficient and timely order fulfillment in fast-paced logistics environments.

Inventory Slotting Automation

A Fulfillment Supervisor specializing in Inventory Slotting Automation leverages AI-driven algorithms to optimize product placement, enhancing picking speed and accuracy within the warehouse. This automation reduces labor costs and improves order fulfillment rates by strategically organizing inventory based on demand patterns and storage efficiency metrics.

Fulfillment Supervisor Infographic

jobdayta.com

jobdayta.com