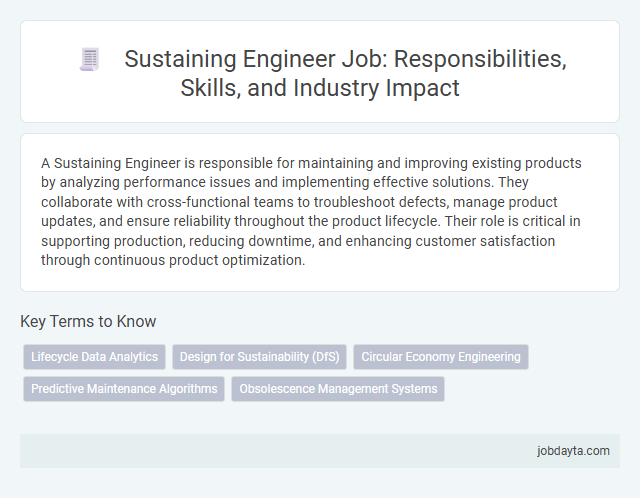

A Sustaining Engineer is responsible for maintaining and improving existing products by analyzing performance issues and implementing effective solutions. They collaborate with cross-functional teams to troubleshoot defects, manage product updates, and ensure reliability throughout the product lifecycle. Their role is critical in supporting production, reducing downtime, and enhancing customer satisfaction through continuous product optimization.

Overview of a Sustaining Engineer Role

A Sustaining Engineer plays a critical role in maintaining and improving existing products and systems. This position ensures the reliability and performance of engineering solutions throughout their lifecycle.

- Product Support - Provides ongoing technical assistance and troubleshooting for released products to resolve customer issues efficiently.

- Continuous Improvement - Implements design modifications and updates to enhance product functionality and address performance deficiencies.

- Cross-Functional Collaboration - Works closely with R&D, quality assurance, and manufacturing teams to sustain product integrity and compliance.

A Sustaining Engineer bridges the gap between product development and customer satisfaction by ensuring long-term product success.

Key Responsibilities of a Sustaining Engineer

| Key Responsibilities of a Sustaining Engineer |

|---|

| Maintaining and improving existing products to ensure consistent performance and reliability |

| Analyzing customer feedback and product data to identify areas for enhancement and defect resolution |

| Collaborating with cross-functional teams including manufacturing, quality assurance, and product development |

| Providing technical support and troubleshooting guidance to resolve complex engineering issues |

| Documenting product updates, design changes, and engineering processes to maintain accurate records |

| Ensuring compliance with industry standards, safety regulations, and internal quality protocols |

| Driving continuous improvement initiatives to extend product lifecycle and reduce operational costs |

| Training and mentoring junior engineers to enhance team expertise and knowledge sharing |

| Using root cause analysis methods to identify and correct systemic product failures |

| Your role includes monitoring product performance metrics and recommending necessary engineering adjustments |

Essential Technical Skills for Sustaining Engineers

What are the essential technical skills for a Sustaining Engineer to excel in their role? Deep knowledge of product lifecycle management and problem-solving abilities ensure issues are resolved efficiently. Mastery of root cause analysis and effective debugging techniques helps maintain product reliability and customer satisfaction.

How important is proficiency in software and hardware troubleshooting for a Sustaining Engineer? Strong troubleshooting skills allow quick identification and correction of defects in complex systems. Familiarity with diagnostic tools and test equipment is crucial to support ongoing maintenance and updates.

Which communication skills enhance the effectiveness of a Sustaining Engineer? Clear documentation and reporting facilitate collaboration among cross-functional teams. Ability to translate technical findings into actionable insights ensures seamless information flow to stakeholders.

Why is knowledge of configuration management vital for Sustaining Engineers? Configuration management maintains product integrity during updates and fixes. Proper version control prevents errors and maintains system stability throughout the sustaining process.

How does expertise in quality assurance improve a Sustaining Engineer's performance? Understanding quality standards and testing procedures helps verify that products meet customer expectations. Implementing continuous improvement practices drives enhanced product durability and reliability.

Problem-Solving and Troubleshooting in Sustaining Engineering

Sustaining Engineers play a critical role in maintaining and improving existing products through effective problem-solving and troubleshooting techniques. They analyze system failures and implement corrective actions to enhance product reliability and performance. Their expertise ensures minimal downtime and maximizes customer satisfaction by resolving complex engineering issues promptly.

Collaboration and Communication in Cross-Functional Teams

Sustaining engineers play a critical role in maintaining product reliability through effective collaboration and communication within cross-functional teams. Clear information exchange between engineering, quality assurance, and customer support ensures timely resolution of product issues.

- Facilitating Interdisciplinary Dialogue - Sustaining engineers bridge gaps between diverse teams by translating technical details into actionable insights for all stakeholders.

- Coordinating Feedback Loops - They organize continuous feedback from customers and production teams to guide iterative improvements and maintain engineering alignment.

- Documenting and Sharing Knowledge - Sustaining engineers create comprehensive knowledge bases that support consistent understanding and communication across departments.

Impact of Sustaining Engineers on Product Lifecycle Management

Sustaining Engineers play a crucial role in Product Lifecycle Management by ensuring continuous product performance and reliability after launch. Their expertise in troubleshooting, maintenance, and incremental improvements minimizes product downtime and extends lifecycle value.

The impact of Sustaining Engineers includes rapid defect resolution and effective change management, which supports long-term customer satisfaction and reduces total cost of ownership. Your organization benefits from their ability to balance engineering resources while maintaining product integrity throughout its lifecycle.

Quality Assurance and Continuous Improvement Practices

Sustaining Engineers play a critical role in maintaining product quality and driving continuous improvement initiatives within engineering processes. Your focus on Quality Assurance ensures that products meet rigorous standards while optimizing performance over time.

- Quality Assurance Implementation - Enforces systematic testing and validation protocols to uphold product integrity throughout the lifecycle.

- Root Cause Analysis - Identifies and resolves underlying issues in manufacturing and design to prevent recurrence and enhance reliability.

- Continuous Improvement Strategies - Applies Lean and Six Sigma methodologies to streamline workflows, reduce defects, and increase operational efficiency.

Tools and Technologies Utilized by Sustaining Engineers

Sustaining Engineers utilize a diverse range of tools and technologies to maintain and improve existing products efficiently. Common tools include Computer-Aided Design (CAD) software for design modifications, version control systems like Git for managing changes, and diagnostic software for troubleshooting. Your expertise in these technologies ensures seamless product sustainment and quality enhancement throughout the lifecycle.

Career Growth and Advancement Opportunities

A Sustaining Engineer plays a crucial role in maintaining and improving existing products, ensuring their reliability and performance over time. This position offers a blend of technical problem-solving and cross-functional collaboration, making it vital for product lifecycle management.

Career growth for a Sustaining Engineer often includes advancing to senior engineering roles, specializing in areas such as quality assurance or product development. Opportunities exist to lead cross-departmental projects, enhancing leadership skills and strategic planning. Continuous learning and certifications in new technologies can further accelerate advancement within engineering management or technical expert tracks.

Industry Trends Influencing Sustaining Engineering Roles

Sustaining engineering roles are evolving rapidly due to advancements in automation and predictive maintenance technologies. These innovations streamline product lifecycle management and enhance system reliability.

The increasing integration of IoT devices in industrial settings demands sustaining engineers to adapt skill sets in data analysis and remote monitoring. Your expertise is crucial in managing these complex, technology-driven environments to ensure continuous product improvement.

Related Important Terms

Lifecycle Data Analytics

Sustaining Engineers leverage lifecycle data analytics to monitor, analyze, and optimize product performance, enabling proactive maintenance and continuous improvement throughout the product lifecycle. By integrating real-time data and historical trends, they enhance reliability, reduce downtime, and inform strategic engineering decisions.

Design for Sustainability (DfS)

Sustaining Engineers integrate Design for Sustainability (DfS) principles by optimizing product lifecycle efficiency, reducing material waste, and enhancing energy efficiency through innovative engineering solutions. Their expertise ensures continuous product improvements align with environmental regulations and sustainability goals to minimize ecological impact throughout the manufacturing and usage phases.

Circular Economy Engineering

Sustaining Engineers in Circular Economy Engineering specialize in designing and maintaining systems that maximize resource efficiency, promote recycling, and extend product lifecycles. Their expertise drives sustainable innovation by integrating lifecycle assessments, waste reduction techniques, and closed-loop manufacturing processes within engineering operations.

Predictive Maintenance Algorithms

Sustaining engineers leverage predictive maintenance algorithms to analyze equipment data, identify potential failures, and optimize maintenance schedules, reducing downtime and operational costs. These algorithms utilize machine learning models and sensor data to predict component wear and failure trends, enabling proactive interventions that extend asset life and enhance system reliability.

Obsolescence Management Systems

Sustaining Engineers specialize in Obsolescence Management Systems by proactively identifying and mitigating risks related to outdated components in engineering products, ensuring long-term reliability and continuous support. They employ advanced tracking tools and predictive analytics to streamline inventory management, prevent costly disruptions, and extend product lifecycle performance.

Sustaining Engineer Infographic

jobdayta.com

jobdayta.com