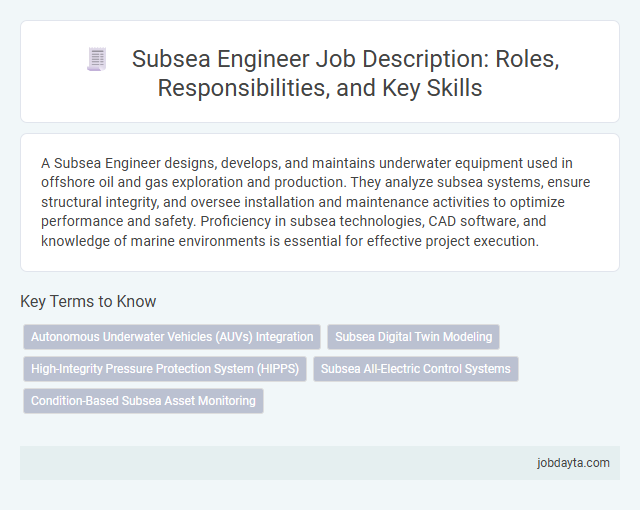

A Subsea Engineer designs, develops, and maintains underwater equipment used in offshore oil and gas exploration and production. They analyze subsea systems, ensure structural integrity, and oversee installation and maintenance activities to optimize performance and safety. Proficiency in subsea technologies, CAD software, and knowledge of marine environments is essential for effective project execution.

Overview of a Subsea Engineer Role

A Subsea Engineer specializes in the design, installation, and maintenance of underwater equipment used in offshore oil and gas production. This role demands expertise in subsea systems, hydraulic controls, and underwater construction technologies.

Subsea Engineers work closely with multidisciplinary teams to ensure safe and efficient operation of subsea infrastructure. Your responsibilities include troubleshooting technical challenges and optimizing subsea production processes.

- Design Expertise - Developing detailed subsea equipment layouts and specifications for underwater applications.

- Installation Oversight - Managing the deployment of subsea systems using remotely operated vehicles and specialized vessels.

- Maintenance and Inspection - Conducting routine checks and repairs to prevent failures and extend equipment life.

Core Responsibilities of a Subsea Engineer

A Subsea Engineer specializes in designing, installing, and maintaining underwater equipment and systems used in offshore oil and gas extraction. They analyze geological and environmental data to ensure structural integrity and operational safety of subsea infrastructure such as pipelines, risers, and wellheads. Their core responsibilities also include troubleshooting technical issues, performing risk assessments, and collaborating with multidisciplinary teams to optimize subsea project performance.

Essential Technical Skills for Subsea Engineers

Subsea engineers play a critical role in offshore oil and gas extraction, specializing in designing and maintaining underwater systems. Mastery of specialized technical skills ensures the safety and efficiency of subsea operations.

- Hydrodynamics Knowledge - Understanding fluid dynamics underwater is essential for designing subsea equipment that can withstand pressure and currents.

- ROV Operation Expertise - Skilled operation of Remotely Operated Vehicles is necessary for inspection, installation, and maintenance tasks in deepwater environments.

- Welding and Materials Proficiency - Familiarity with subsea welding techniques and corrosion-resistant materials enables durable pipeline and structural repairs.

Educational Qualifications and Certifications Required

What educational qualifications are essential for a Subsea Engineer? A bachelor's degree in Mechanical, Civil, or Ocean Engineering forms the foundation. Specialized courses in subsea systems and offshore engineering enhance relevant skills.

Which certifications are typically required for a Subsea Engineer? Certification in subsea technology from recognized institutions like the Society for Underwater Technology (SUT) is often necessary. Additional safety qualifications such as BOSIET and IMCA certifications are valuable for offshore work.

Key Tools and Technologies Used in Subsea Engineering

Subsea engineers specialize in designing, installing, and maintaining equipment used in underwater oil and gas extraction. Key tools include remotely operated vehicles (ROVs), subsea control modules (SCMs), and hydraulic intervention systems. Technologies such as advanced sonar mapping, subsea robotics, and pipeline inspection gauges (PIGs) ensure efficient and safe operations in challenging deepwater environments.

Safety and Compliance in Subsea Engineering

Subsea engineers play a crucial role in ensuring safety and compliance during underwater operations. Their expertise helps prevent accidents and environmental hazards in complex subsea environments.

Strict adherence to industry standards and regulatory frameworks is vital for maintaining operational integrity. You can rely on advanced safety protocols and rigorous inspections to uphold compliance throughout the project lifecycle.

Collaboration and Teamwork in Subsea Projects

| Role | Subsea Engineer |

|---|---|

| Core Focus | Collaboration and Teamwork in Subsea Projects |

| Importance of Collaboration | Key to managing complex subsea systems, ensuring safety, efficiency, and project success. |

| Team Composition | Multidisciplinary professionals including marine engineers, geotechnical experts, welding specialists, and ROV operators. |

| Collaboration Tools | Subsea project management software, 3D modeling platforms, real-time communication systems, and integrated data dashboards. |

| Project Phases | Concept design, detailed engineering, procurement, installation, commissioning, and maintenance. |

| Communication Channels | Daily coordination meetings, cross-discipline workshops, shared reporting platforms, and remote video conferencing. |

| Benefits of Teamwork | Enhanced problem-solving, reduced risk of failures, optimized resource allocation, faster decision-making, and increased innovation. |

| Challenges Addressed | Subsea environmental conditions, equipment failure risks, logistics complexities, and compliance with safety regulations. |

| Outcome | Successful delivery of subsea projects with improved operational reliability and cost efficiency. |

Challenges Faced by Subsea Engineers

Subsea engineers tackle complex challenges in deepwater environments where pressure and temperature extremes demand precise technical solutions. Ensuring the integrity of underwater pipelines and equipment is critical to prevent failures and environmental hazards.

Remote operation and maintenance require advanced robotics and real-time monitoring systems to overcome accessibility issues. You must also navigate stringent regulatory standards and coordinate with multidisciplinary teams to deliver safe and efficient subsea projects.

Career Path and Growth Opportunities for Subsea Engineers

Subsea engineering offers a dynamic career path focused on the design, installation, and maintenance of underwater equipment and infrastructure. Professionals in this field contribute to offshore oil and gas production, renewable energy, and deepwater exploration projects.

- Entry-Level Opportunities - Graduates typically start as junior subsea engineers, gaining hands-on experience with subsea systems and project support.

- Mid-Level Advancement - Engineers advance by managing subsea projects, conducting risk assessments, and optimizing equipment performance.

- Senior Leadership Roles - Experienced subsea engineers lead multidisciplinary teams and influence strategic decisions within large-scale offshore developments.

Continuous professional development and certifications enhance career growth and global mobility for subsea engineers.

Impact of Subsea Engineers on Offshore Oil and Gas Industry

Subsea Engineers play a critical role in the offshore oil and gas industry by designing, installing, and maintaining underwater infrastructure. Their expertise ensures the reliability and safety of subsea systems essential for hydrocarbon extraction.

These engineers use advanced technology to optimize subsea production systems, reducing downtime and operational costs. They perform risk assessments and develop innovative solutions to withstand harsh underwater environments. Your success in offshore projects heavily relies on the precision and skill that Subsea Engineers bring to complex subsea challenges.

Related Important Terms

Autonomous Underwater Vehicles (AUVs) Integration

Subsea engineers specializing in Autonomous Underwater Vehicles (AUVs) integration design and implement advanced robotic systems for underwater exploration and infrastructure inspection, enhancing efficiency and safety in deep-sea operations. Expertise in sensor fusion, communication protocols, and navigation algorithms enables seamless AUV deployment, data acquisition, and real-time monitoring in complex subsea environments.

Subsea Digital Twin Modeling

Subsea digital twin modeling integrates real-time sensor data and advanced simulation techniques to create virtual replicas of underwater infrastructure, enabling predictive maintenance and risk assessment. This technology enhances operational efficiency by providing engineers with accurate insights into subsea equipment performance and environmental conditions.

High-Integrity Pressure Protection System (HIPPS)

Subsea Engineers specializing in High-Integrity Pressure Protection Systems (HIPPS) design and implement critical safety systems that prevent overpressure scenarios in offshore facilities, ensuring subsea pipeline and equipment integrity. Their expertise includes selecting materials and components that withstand extreme underwater conditions while complying with industry standards such as API 16S and ISO 10423.

Subsea All-Electric Control Systems

Subsea engineers specializing in all-electric control systems design, install, and maintain advanced electric actuation and control technologies that replace traditional hydraulic systems in underwater environments, enhancing reliability and reducing environmental risks. These engineers leverage digital communication protocols and robust electric power distribution to ensure precise control of subsea valves, pumps, and sensors in offshore oil and gas production.

Condition-Based Subsea Asset Monitoring

Condition-Based Subsea Asset Monitoring enables subsea engineers to optimize maintenance schedules by analyzing real-time data from sensors embedded in underwater infrastructure. This approach reduces unplanned downtime and extends the lifecycle of critical assets such as pipelines, wellheads, and manifolds through predictive analytics and early fault detection.

Subsea Engineer Infographic

jobdayta.com

jobdayta.com