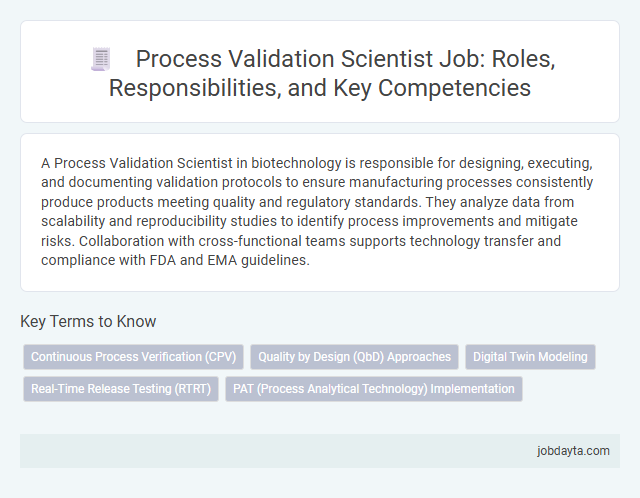

A Process Validation Scientist in biotechnology is responsible for designing, executing, and documenting validation protocols to ensure manufacturing processes consistently produce products meeting quality and regulatory standards. They analyze data from scalability and reproducibility studies to identify process improvements and mitigate risks. Collaboration with cross-functional teams supports technology transfer and compliance with FDA and EMA guidelines.

Introduction to Process Validation Scientist Role

A Process Validation Scientist plays a crucial role in the biotechnology industry by ensuring manufacturing processes consistently produce products that meet quality standards. This role involves designing, executing, and analyzing validation protocols to guarantee process reliability and regulatory compliance.

- Quality Assurance Integration - Collaborates with quality assurance teams to develop validation strategies aligned with regulatory guidelines such as FDA and EMA requirements.

- Data Analysis Expertise - Utilizes statistical tools and scientific methods to interpret validation data and identify process variability or deviations.

- Cross-Functional Coordination - Works closely with manufacturing, R&D, and engineering departments to ensure seamless implementation and continuous improvement of validated processes.

Key Responsibilities of a Process Validation Scientist

Process Validation Scientists play a critical role in ensuring the reliability and quality of biotechnological manufacturing processes. Their work supports regulatory compliance and product consistency throughout production.

- Designing Validation Protocols - Develop and implement detailed validation protocols to assess critical process parameters and ensure process reproducibility.

- Data Analysis and Reporting - Analyze validation data, generate comprehensive reports, and provide actionable insights to improve process robustness and compliance.

- Cross-Functional Collaboration - Work closely with manufacturing, quality assurance, and regulatory teams to align validation activities with industry standards and regulatory requirements.

Expertise in process validation supports the development of safe and effective biopharmaceutical products.

Essential Skills and Competencies Required

A Process Validation Scientist plays a crucial role in ensuring biopharmaceutical manufacturing processes meet strict quality and regulatory standards. Expertise in analytical techniques and data interpretation is essential to validate and optimize these processes effectively.

Strong knowledge of Good Manufacturing Practices (GMP) and regulatory guidelines such as FDA and EMA is vital for compliance. Your ability to design validation protocols and analyze process performance data drives consistent product quality and safety.

Educational and Professional Qualifications

What educational background is essential for a Process Validation Scientist in biotechnology? A bachelor's degree in biotechnology, biochemistry, or related fields is typically required. Advanced degrees such as a master's or PhD enhance expertise and career prospects in process validation.

Which professional qualifications strengthen your suitability as a Process Validation Scientist? Experience in Good Manufacturing Practices (GMP) and knowledge of regulatory guidelines like FDA and ICH are crucial for ensuring compliant validation processes. Certifications in quality assurance or process validation methodologies further establish professional credibility.

Overview of Process Validation in Biotechnology

Process validation in biotechnology ensures that manufacturing processes consistently produce products meeting predefined quality standards. It involves systematic evaluation and documentation to confirm process reliability and compliance with regulatory requirements.

As a Process Validation Scientist, you play a crucial role in designing and executing validation protocols that safeguard product safety and efficacy. Your expertise drives continuous process improvement and supports regulatory submissions in the biotechnology industry.

Tools and Technologies Utilized

Process Validation Scientists employ advanced tools such as automated data acquisition systems, statistical software, and real-time monitoring technologies to ensure bioprocess consistency and product quality. Cutting-edge technologies like PAT (Process Analytical Technology) and HPLC (High-Performance Liquid Chromatography) are integral for accurate validation and process control. Your role benefits from integrated software platforms that streamline data analysis and enhance decision-making efficiency in biopharmaceutical manufacturing.

Challenges Faced by Process Validation Scientists

Process Validation Scientists in biotechnology encounter challenges such as ensuring consistent product quality amid complex manufacturing processes. You must navigate strict regulatory requirements while integrating advanced analytical technologies for accurate validation. Maintaining robust documentation and adapting to evolving standards remain critical obstacles throughout the validation lifecycle.

Career Growth and Opportunities

| Career Growth | Process Validation Scientists in biotechnology experience rapid career advancement by ensuring manufacturing processes meet quality and regulatory standards. Expertise in process validation enhances your ability to lead projects and contribute to product development, increasing professional value within organizations. |

|---|---|

| Opportunities | There is a growing demand for skilled Process Validation Scientists due to stringent regulatory requirements from agencies like FDA and EMA. Opportunities exist in pharmaceutical companies, biotech startups, and contract manufacturing organizations. Skills in automation, data analysis, and continuous process verification open doors to specialized and leadership roles. |

| Skill Development | Mastering statistical tools, validation protocols, and regulatory guidelines significantly improves career prospects. Professional certifications in Good Manufacturing Practices (GMP) and quality assurance elevate credibility and employability in competitive biotechnology sectors. |

| Impact on Biotechnology | Process Validation Scientists play a critical role in product consistency and patient safety, driving innovation in biopharmaceutical manufacturing. Your expertise supports regulatory submissions and accelerates time-to-market for life-saving therapies, highlighting the strategic importance of this career path. |

Impact of Process Validation on Product Quality and Compliance

Process Validation Scientists play a critical role in ensuring the consistency and reliability of biotechnological manufacturing processes. Their work directly impacts product quality by confirming that processes produce results meeting predetermined specifications.

Effective process validation minimizes batch-to-batch variability, reducing the risk of defective products. This validation supports regulatory compliance by providing documented evidence that manufacturing processes are controlled and robust. Consequently, it protects patient safety and enhances the overall efficiency of biopharmaceutical production.

Conclusion: The Future of Process Validation Scientists in Biotech

The role of Process Validation Scientists in biotechnology is evolving with advancements in technology and regulatory expectations. Their expertise is critical to ensuring product quality and compliance in increasingly complex biomanufacturing processes.

- Integration of AI and Machine Learning - Process Validation Scientists are utilizing AI-driven analytics to enhance process understanding and predictive capabilities.

- Emphasis on Continuous Validation - The shift towards continuous process verification requires scientists to adopt new methodologies for real-time monitoring and control.

- Expansion of Regulatory Knowledge - Staying current with global regulatory frameworks is essential to effectively navigate validation requirements and ensure product approval.

Related Important Terms

Continuous Process Verification (CPV)

Process Validation Scientists specializing in Continuous Process Verification (CPV) play a critical role in ensuring the consistent quality and compliance of biotechnological manufacturing processes by continuously monitoring and analyzing critical process parameters and quality attributes throughout the product lifecycle. Their expertise in CPV enables proactive identification of process deviations and implementation of corrective actions, enhancing process robustness and regulatory adherence in biologics production.

Quality by Design (QbD) Approaches

Process Validation Scientists specializing in Quality by Design (QbD) approaches leverage systematic risk assessment and design of experiments (DoE) to define critical process parameters and ensure robust biomanufacturing processes. Their expertise enhances product consistency and regulatory compliance by integrating comprehensive data analysis and process control strategies throughout development and commercial production.

Digital Twin Modeling

Process Validation Scientists specializing in Digital Twin Modeling leverage advanced simulation technologies to create virtual replicas of bioprocesses, enabling predictive analytics and enhanced process control. These digital models facilitate real-time monitoring and optimization, ensuring consistent product quality and regulatory compliance in biomanufacturing.

Real-Time Release Testing (RTRT)

Process Validation Scientists specializing in Real-Time Release Testing (RTRT) employ advanced analytical technologies to continuously monitor critical quality attributes during biopharmaceutical manufacturing, ensuring product safety and efficacy without the need for end-product testing. Their expertise in statistical process control and regulatory compliance accelerates batch release timelines and enhances overall process robustness in biotechnology production.

PAT (Process Analytical Technology) Implementation

Process Validation Scientists specializing in PAT implementation develop and execute analytical strategies to monitor and control biotechnological manufacturing processes in real time, ensuring consistent product quality and compliance with regulatory standards. They leverage advanced sensor technologies, data analytics, and process control tools to optimize bioprocess efficiency, reduce variability, and enhance overall process robustness in biopharmaceutical production.

Process Validation Scientist Infographic

jobdayta.com

jobdayta.com