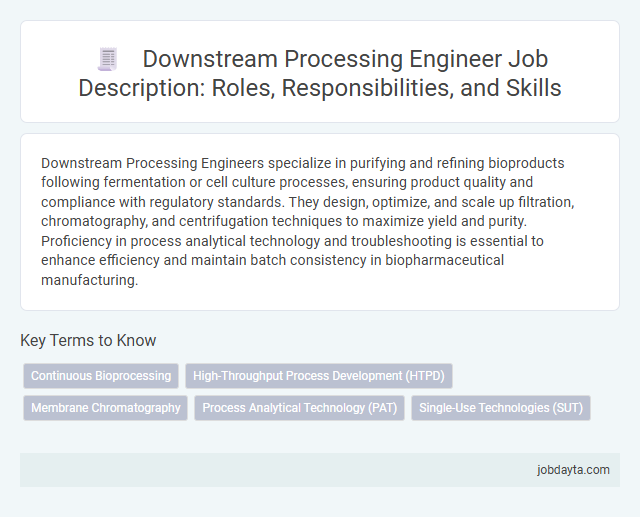

Downstream Processing Engineers specialize in purifying and refining bioproducts following fermentation or cell culture processes, ensuring product quality and compliance with regulatory standards. They design, optimize, and scale up filtration, chromatography, and centrifugation techniques to maximize yield and purity. Proficiency in process analytical technology and troubleshooting is essential to enhance efficiency and maintain batch consistency in biopharmaceutical manufacturing.

Overview of a Downstream Processing Engineer in Biotechnology

Downstream Processing Engineers play a critical role in biotechnology by purifying and isolating biologically active products. Their work ensures that pharmaceutical and therapeutic compounds meet stringent quality and safety standards.

- Role in Purification - Downstream Processing Engineers design and optimize processes to extract target biomolecules from fermentation broths or cell cultures.

- Quality Assurance - They implement purification techniques that guarantee product consistency, purity, and potency in compliance with regulatory guidelines.

- Process Optimization - Engineers utilize chromatography, filtration, and centrifugation methods to enhance yield and reduce production costs efficiently.

Expertise in downstream processing techniques is essential for advancing biopharmaceutical production and innovation.

Key Roles and Responsibilities of a Downstream Processing Engineer

A Downstream Processing Engineer plays a crucial role in biotechnology by purifying and isolating biological products after production. You ensure the quality and consistency of biopharmaceuticals through efficient extraction, separation, and purification methods.

Responsibilities include designing and optimizing filtration, chromatography, and centrifugation processes to meet regulatory standards. Interpreting data to troubleshoot process deviations and improve yield are vital parts of maintaining product safety and efficacy.

Essential Skills Required for Downstream Processing Engineers

| Essential Skills Required for Downstream Processing Engineers |

|---|

|

Technical Expertise: Strong knowledge of bioprocess engineering principles, including chromatography, filtration, centrifugation, and extraction techniques. Analytical Skills: Ability to analyze process data, interpret chromatograms, and optimize purification steps to ensure product quality and yield. Process Development: Experience with scaling up lab processes to industrial production, including troubleshooting and process optimization. Regulatory Knowledge: Familiarity with Good Manufacturing Practices (GMP), regulatory guidelines, and documentation standards critical for compliance. Problem-Solving: Capacity to identify process bottlenecks, implement corrective actions, and maintain continuous improvement in downstream operations. Attention to Detail: Precision in monitoring process parameters and meticulous record-keeping to maintain product integrity. Team Collaboration: Effective communication skills to work alongside upstream engineers, quality assurance, and production teams. Laboratory Skills: Proficiency in using laboratory instruments and software for process simulation and control. Project Management: Ability to plan, prioritize, and execute multiple downstream processing tasks efficiently. Your Role: Applying these skills ensures the successful purification and recovery of biomolecules critical to biotechnology product manufacturing. |

Day-to-Day Tasks in Downstream Processing Engineering

Downstream Processing Engineers specialize in the purification and recovery of bioproducts from fermentation or cell culture processes. They monitor and optimize techniques such as chromatography, filtration, and centrifugation to ensure product quality and yield. Daily responsibilities include maintaining equipment, analyzing process data, and troubleshooting issues to support efficient biomanufacturing.

Importance of Downstream Processing in Biopharmaceutical Production

Downstream processing is a critical phase in biopharmaceutical production that ensures the purification and isolation of target biomolecules. This step guarantees product safety, efficacy, and regulatory compliance, making it indispensable in the manufacturing pipeline.

Your role as a Downstream Processing Engineer involves optimizing techniques such as chromatography, filtration, and centrifugation to maximize yield and purity. Efficient downstream processing reduces production costs and speeds up time-to-market for vital therapeutics.

Educational and Professional Qualifications for Downstream Processing Engineers

Downstream Processing Engineers in biotechnology require specialized educational backgrounds and professional training to efficiently separate and purify biological products. Your qualifications must align with industry standards to ensure high-quality production and compliance.

- Bachelor's Degree in Biotechnology or Chemical Engineering - Provides foundational knowledge in bioprocessing and molecular biology essential for downstream operations.

- Master's or PhD in Bioprocess Engineering - Enhances expertise in advanced purification techniques and process optimization for complex biologics.

- Industry Certifications and Training - Demonstrates proficiency in GMP compliance, chromatography, filtration, and analytical methods critical for downstream processing.

Common Challenges Faced by Downstream Processing Engineers

What are the common challenges faced by downstream processing engineers in biotechnology?

Downstream processing engineers often encounter difficulties related to product purification and yield optimization. Managing impurities and scaling processes from lab to industrial levels remain critical obstacles in bioprocess development.

Tools and Technologies Used in Downstream Processing

Downstream Processing Engineers utilize advanced chromatography systems to separate and purify biomolecules with high precision. Ultrafiltration and microfiltration technologies enable efficient concentration and clarification of products in bioprocessing workflows. You rely on automated control systems and real-time analytics to optimize yield and ensure product consistency.

Career Growth and Opportunities in Downstream Processing Engineering

Downstream Processing Engineers play a crucial role in biotechnology by purifying and isolating biological products with high precision. Career growth in this field offers opportunities to work with cutting-edge technologies and contribute to pharmaceutical, agricultural, and industrial innovations.

- High Demand in Biopharmaceutical Industry - There is an increasing need for engineers skilled in chromatography, filtration, and purification to support biopharmaceutical manufacturing.

- Advancement through Specialization - Expertise in process optimization and scale-up techniques opens doors to senior roles and project management positions.

- Integration of Automation and Data Analytics - Knowledge of automation systems and analytics enhances efficiency and offers competitive advantages in the job market.

Impact of Downstream Processing Engineers on Product Quality and Safety

Downstream Processing Engineers play a critical role in biotechnology by ensuring the purification and refinement of bioproducts meet stringent quality and safety standards. Their expertise directly impacts the efficacy and safety of pharmaceuticals, vaccines, and other biologics.

They design and optimize processes such as filtration, chromatography, and centrifugation to remove impurities and contaminants effectively. Maintaining product integrity through precise control of processing parameters reduces the risk of degradation and contamination. Their work guarantees compliance with regulatory guidelines, ultimately protecting patient health and advancing biotechnological innovation.

Related Important Terms

Continuous Bioprocessing

Downstream Processing Engineers specializing in Continuous Bioprocessing optimize the purification and separation of biologics by integrating continuous flow techniques, enhancing product yield and process efficiency. Their expertise in real-time monitoring and automation drives scalable production of high-quality therapeutic proteins and vaccines.

High-Throughput Process Development (HTPD)

Downstream Processing Engineers specializing in High-Throughput Process Development (HTPD) optimize purification workflows using automated techniques to accelerate bioprocess scalability and product yield. They integrate advanced liquid handling systems, real-time analytics, and data-driven modeling to enhance process efficiency and ensure consistent quality in biopharmaceutical manufacturing.

Membrane Chromatography

Downstream Processing Engineers specializing in membrane chromatography optimize purification steps to enhance biomolecule yield and purity by leveraging ultrafiltration and diafiltration techniques. Expertise in scalable membrane technologies and process integration ensures efficient separation of target proteins, critical for biopharmaceutical manufacturing and regulatory compliance.

Process Analytical Technology (PAT)

A Downstream Processing Engineer specializing in Process Analytical Technology (PAT) leverages real-time monitoring tools to optimize bioprocess efficiency and product quality in biopharmaceutical manufacturing. Implementation of PAT enables precise control over purification steps such as chromatography and filtration, reducing batch variability and ensuring compliance with regulatory standards.

Single-Use Technologies (SUT)

Downstream Processing Engineers specializing in Single-Use Technologies (SUT) optimize bioprocess workflows by implementing disposable systems to enhance product purity and reduce contamination risk in biologics manufacturing. Expertise in sterile filtration, chromatography, and aseptic assembly within SUT frameworks ensures scalable, cost-effective purification of therapeutic proteins and vaccines.

Downstream Processing Engineer Infographic

jobdayta.com

jobdayta.com