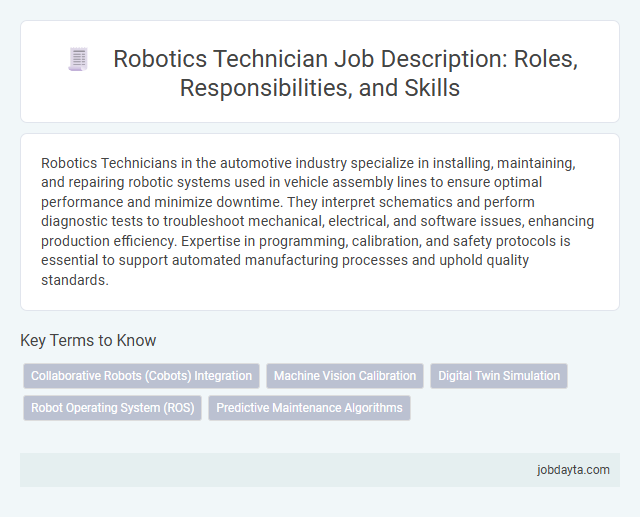

Robotics Technicians in the automotive industry specialize in installing, maintaining, and repairing robotic systems used in vehicle assembly lines to ensure optimal performance and minimize downtime. They interpret schematics and perform diagnostic tests to troubleshoot mechanical, electrical, and software issues, enhancing production efficiency. Expertise in programming, calibration, and safety protocols is essential to support automated manufacturing processes and uphold quality standards.

Overview of a Robotics Technician in Automotive Industry

A Robotics Technician in the automotive industry specializes in maintaining and repairing robotic equipment used in vehicle manufacturing. These technicians ensure that robotic systems operate efficiently to support production lines and improve assembly processes.

- Robotic System Maintenance - Performs routine inspections and troubleshooting of automated machinery to prevent production downtime.

- Programming and Calibration - Adjusts robotic controls and programs to optimize precision and speed in automotive assembly tasks.

- Safety Compliance - Implements safety protocols to protect workers and equipment during robotic operation and maintenance.

Key Roles and Responsibilities of Robotics Technicians

| Key Roles | Responsibilities |

|---|---|

| Installation of Robotic Systems | Set up and configure robotic machinery used in automotive assembly lines to ensure optimal performance. |

| Maintenance and Repair | Perform routine inspections, troubleshoot malfunctions, and repair robotic equipment to minimize production downtime. |

| Programming and Calibration | Develop and adjust software programs for precise robotic movements and operational efficiency in automotive manufacturing. |

| Quality Control | Monitor robotic system outputs to maintain adherence to automotive industry standards and improve product quality. |

| Safety Compliance | Ensure all robotic operations meet safety regulations to protect workers and equipment in automotive plants. |

| Collaboration with Engineering Teams | Work closely with mechanical and automotive engineers to enhance robotic integration and system advancements. |

| Documentation and Reporting | Maintain detailed records of maintenance activities, system updates, and operational issues for process optimization. |

Essential Technical Skills for Automotive Robotics Technicians

Mastering programming languages such as Python and C++ is essential for automotive robotics technicians to effectively control robotic systems. Proficiency in diagnosing and troubleshooting mechanical and electronic components ensures minimal downtime and optimal performance. You must also be skilled in using advanced diagnostic tools and software to maintain and calibrate robotic equipment accurately.

Daily Tasks and Workflow in Robotics Maintenance

Robotics Technicians in automotive manufacturing perform daily diagnostics, calibrations, and repairs on robotic systems to ensure seamless production. You monitor robot performance, troubleshoot mechanical or software issues, and update control systems regularly. Maintaining precise documentation of maintenance activities supports workflow efficiency and minimizes downtime in automotive assembly lines.

Troubleshooting and Repair in Automotive Robotics

What are the key skills required for troubleshooting and repair in automotive robotics? Automotive robotics technicians must have strong diagnostic abilities to identify complex mechanical and electronic issues. Expertise in programming and electrical systems enhances efficiency in repairing advanced robotic components.

How do technicians approach troubleshooting problems in automotive robotics systems? Technicians use specialized diagnostic tools to analyze system errors and malfunctions. They systematically isolate faults to ensure precise repairs and minimize downtime in production lines.

Why is regular maintenance critical for automotive robotic systems? Preventive maintenance helps detect wear and potential failures before they cause major breakdowns. Consistent upkeep extends the lifespan and operational reliability of robotic machinery.

What role does software play in the repair of automotive robotics? Software updates and recalibration are essential aspects of troubleshooting robotic systems. Correcting software faults often restores proper robot function without needing hardware replacement.

How do advancements in artificial intelligence impact troubleshooting in automotive robotics? AI-driven diagnostics enable faster identification of issues by analyzing large amounts of operational data. This technology supports predictive maintenance and reduces unexpected equipment failures.

Importance of Robotics Technicians for Automotive Manufacturing

Robotics technicians play a crucial role in automotive manufacturing by ensuring the seamless operation and maintenance of automated systems. Their expertise enhances production efficiency and minimizes downtime in highly automated assembly lines.

You rely on skilled robotics technicians to troubleshoot complex robotic machinery, improving both safety and product quality. Their work supports innovation and precision, driving advancements in automotive technology.

Required Educational Background and Certifications

Robotics Technicians in the automotive industry must have a solid educational background in robotics, electronics, or mechatronics. Your training should include hands-on experience with automated systems used in vehicle manufacturing.

- Associate Degree in Robotics or Electronics - A foundational education typically requiring two years of study in technical colleges or community colleges.

- Certification in Robotics Technology - Industry-recognized certifications validate expertise in maintaining and programming robotic systems.

- Safety and Technical Training - Specialized courses on automotive robotics safety standards and advanced troubleshooting are essential.

Safety Protocols and Compliance in Robotics Handling

Robotics technicians in the automotive industry must strictly adhere to safety protocols to prevent accidents and ensure operational efficiency. Compliance with industry standards and regulations is critical for maintaining a safe work environment during robotics handling.

- Risk Assessment - Conduct thorough risk assessments to identify potential hazards associated with robotics systems.

- Personal Protective Equipment (PPE) - Use appropriate PPE such as gloves and safety glasses to minimize injury risks when working with robotics.

- Regulatory Compliance - Follow OSHA and ISO robotics safety standards to meet legal and safety requirements in automotive manufacturing.

Consistent training and documentation ensure robotics technicians remain updated on safety practices and compliance obligations.

Career Growth and Advancement Opportunities

Robotics technicians in the automotive industry play a crucial role in maintaining and optimizing automated production systems. Their expertise ensures efficient assembly lines and reduces downtime, directly impacting manufacturing quality and speed.

Career growth opportunities for robotics technicians include advancing to roles such as robotics engineers or automation specialists. Continuous training in programming, system integration, and emerging technologies enhances prospects for leadership positions within automotive manufacturing plants.

Future Trends Impacting Robotics Technician Roles in Automotive

The role of Robotics Technicians in the automotive industry is evolving rapidly due to advancements in automation and artificial intelligence. Cutting-edge technologies are reshaping production lines, requiring technicians to adapt and expand their skill sets.

Future trends such as collaborative robots (cobots), predictive maintenance using IoT sensors, and enhanced machine learning algorithms will significantly impact your daily responsibilities. Robotics Technicians must become proficient in programming, system diagnostics, and real-time data analysis to keep pace with smart manufacturing environments. Continuous learning and adaptation will be essential to maintain efficiency and safety in increasingly automated automotive factories.

Related Important Terms

Collaborative Robots (Cobots) Integration

Robotics Technicians specializing in Collaborative Robots (Cobots) Integration enhance automotive manufacturing by programming, maintaining, and troubleshooting cobots to improve assembly line efficiency and safety. Expertise in cobot sensors, artificial intelligence algorithms, and human-robot interaction protocols drives seamless integration and boosts productivity in automotive plants.

Machine Vision Calibration

Robotics technicians specializing in machine vision calibration ensure the precise alignment and functionality of cameras and sensors critical for automated automotive manufacturing processes. Accurate calibration enhances defect detection, improves robotic assembly accuracy, and optimizes quality control within automotive production lines.

Digital Twin Simulation

Robotics Technicians specializing in Digital Twin Simulation leverage advanced CAD models and real-time sensor data to create precise virtual replicas of automotive manufacturing systems, enabling predictive maintenance and process optimization. Utilizing IoT integration and AI-driven analytics, these simulations enhance robotic assembly line efficiency, reduce downtime, and improve overall vehicle production quality.

Robot Operating System (ROS)

Robotics Technicians specializing in the automotive industry leverage Robot Operating System (ROS) to enhance robotic vehicle assembly and maintenance through advanced sensor integration and real-time diagnostics. Proficiency in ROS enables seamless communication between robotic components, driving efficiency and precision in automated manufacturing processes.

Predictive Maintenance Algorithms

Robotics technicians in the automotive industry utilize predictive maintenance algorithms to analyze sensor data and foresee potential equipment failures, optimizing robotic system uptime. These algorithms employ machine learning models to detect anomalies in robotic arms and assembly line machinery, reducing unplanned downtime and maintenance costs.

Robotics Technician Infographic

jobdayta.com

jobdayta.com